Optris: When Temperature Matters

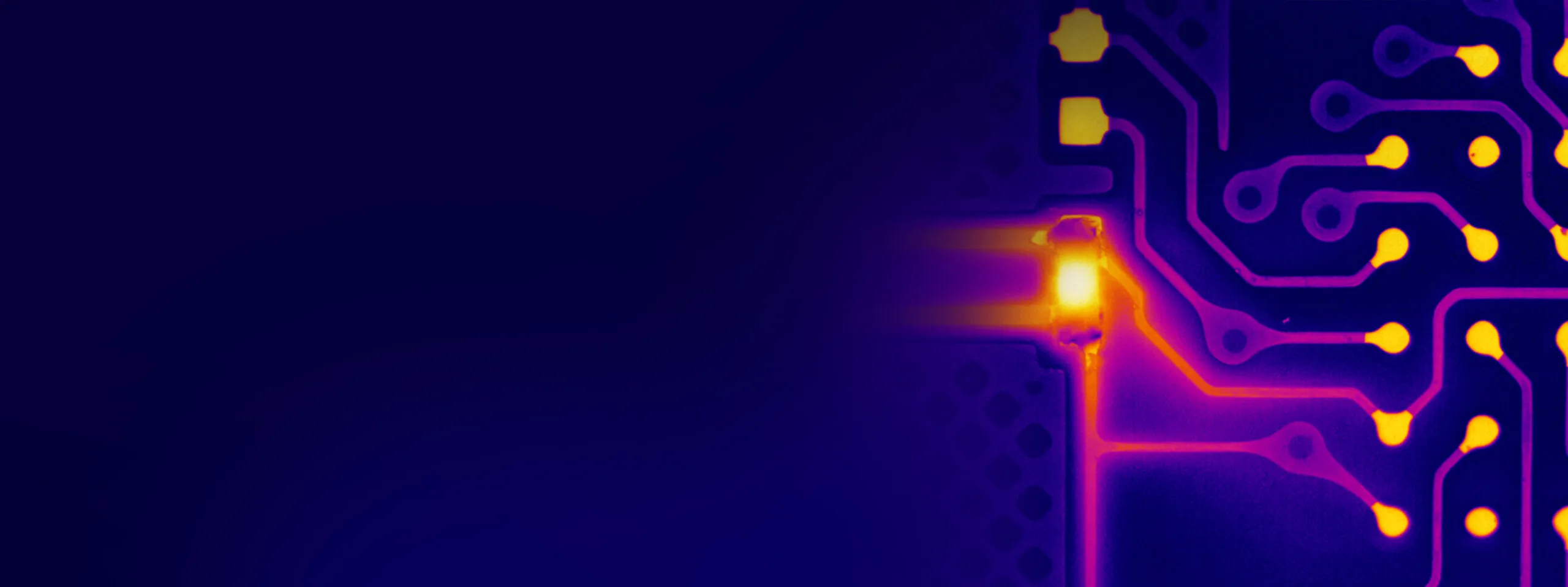

Affordable non-contact accurate temperature measurement for industry and R&D

Choose your Application:

20 years of Innovations and Excellence in IR technology

Optris has been developing and manufacturing affordable innovative infrared measurement devices for non-contact temperature measurement, including infrared cameras, and stationary industrial infrared sensors for area and point measurement, for more than 20 years.

Our comprehensive product portfolio comprises infrared measurement devices for different industrial applications as well as research & development. Our measurement devices enable constant monitoring and control of virtually every manufacturing process, and reductions in energy consumption and production costs through specific process optimization.

About OptrisProduct Highlights

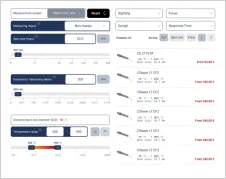

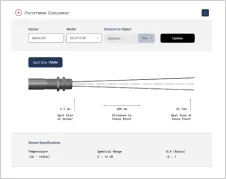

License-Free Software for Infrared Cameras and IR Sensors for non-contact Temperature Measurements

The Optris software, which is free and license-free, is designed for use with Optris IR cameras or IR pyrometers. It is well-suited for visualizing temperature measurements and provides comprehensive control over all Optris sensors. In addition to visualization, the software offers customizable features such as plotting temperature profiles, temperature-time diagrams, alarming, recording, adjusting process controls, and defining programmable outputs and inputs. The software and the APIs are continuously updated and maintained.

The software packages are optimized for easy integration and ease of use. Connectivity is simple, whether through USB, Ethernet, or analog interfaces. Furthermore, with standard protocol support, integration into existing systems is seamless, enhancing standalone monitoring capabilities.

Optris Software

Trusted by Industry & Research

“With Optris we have a very wide spectrum of different devices, so that we are always able to select the optimum resolution and the appropriate lens.”

Kirsten Köhn

CEO, IRIS GmbH

“There are lots of benefits of using the optris CT LT22

pyrometers in our applications. They are really compact and

able to withstand even the high ambient temperatures that prevail

right behind the infrared radiators, which is where we install

them.”

Christian Herrmann

Development Engineer Lightweight Construction,

KraussMaffei

“Since we have been using Optris

pyrometers – and we started way back in 2010 – we have not

had a single device failure.”

Dr. Mesut Cetin

Head of Productmanagement,

KraussMaffei

“To date, the number of production errors in pre-series production

has been significantly reduced thanks to the constant temperature profile of the Optris PI thermal imaging camera.”

Dipl.-Ing. Michael Northington

Process developer R&D

Jacob Plastics GmbH

“Before we contacted Optris, we had already tested a measuring system from another manufacturer. However, this never worked satisfactorily, which is why we looked for alternatives. The cooperation with the experts from Optris for our new temperature measurement technology worked really well.”

Sascha Reinelt

IT and control technology

BarteltGLASBerlin GmbH & Co. KG

“I searched the market for a long time here before I found a suitable infrared camera that met all the requirements. With Optris equipment, the temperature in the kiln can be determined quickly and easily and the quality of the temperature distribution can be controlled. The whole system works according to the Plug & Play principle and is accordingly quickly set up. The evaluation of the data and thermal images works perfectly”

Helmut Hofer

Master Electrician and CEO

Hofer Elektrotechnik

“All in all, the Optris infrared camera is excellently suited to our purposes. It’s

compact and hence easy to integrate mechanically and simple to operate.”

Dr.-Ing. Tim Lantzsch

Head of Laser Powder Bed Fusion department

Fraunhofer Institute for Laser Technology ILT

“With our machines, we can also print components made of titanium, although a high level of smoke generation cannot be avoided. For this reason, we will probably use the Optris pyrometers from the CTratio series in our machines in the future, if the customer wants to print components made of titanium.”

Martin Lange

Development engineer, product development

GEFERTEC GmbH

“The customer is very satisfied with the solution and the Optris cameras used in it. The machine operators only carry out a reference measurement once a week – otherwise the system runs absolutely maintenance-free.”

“For example, we added additives to the melt during the comparative measurements, which caused a lot of smoke to form. The measurement with the PI 05M camera from Optris was nevertheless very precise.”

Thomas Voss

Product Manager,

INDUGA Industrieöfen und Giesserei-Anlagen GmbH & Co. KG

Events

Come and meet our IR temperature measurement experts at the following events.

Talk to us about your IR Temperature Measurement Requirements

Our Infrared Temperature Measurement experts can help you find the right Optris product for your application.

Sign up to the Optris Newsletter

Enter your details below to receive occasional emails with Optris product and company news.