Profibus DP Interface-Kit

The Profibus DP interface is a robust fieldbus protocol used in automation for efficient data exchange.

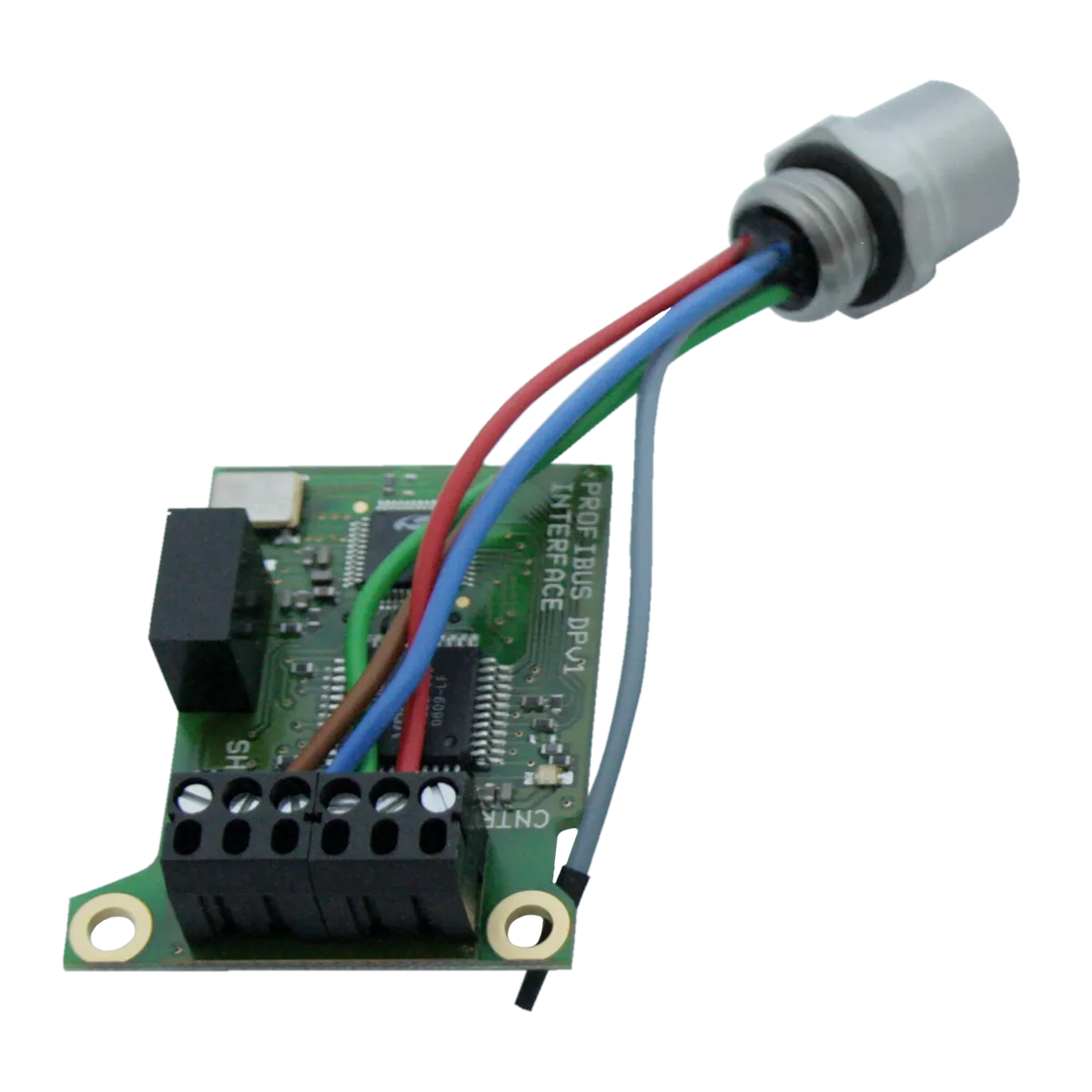

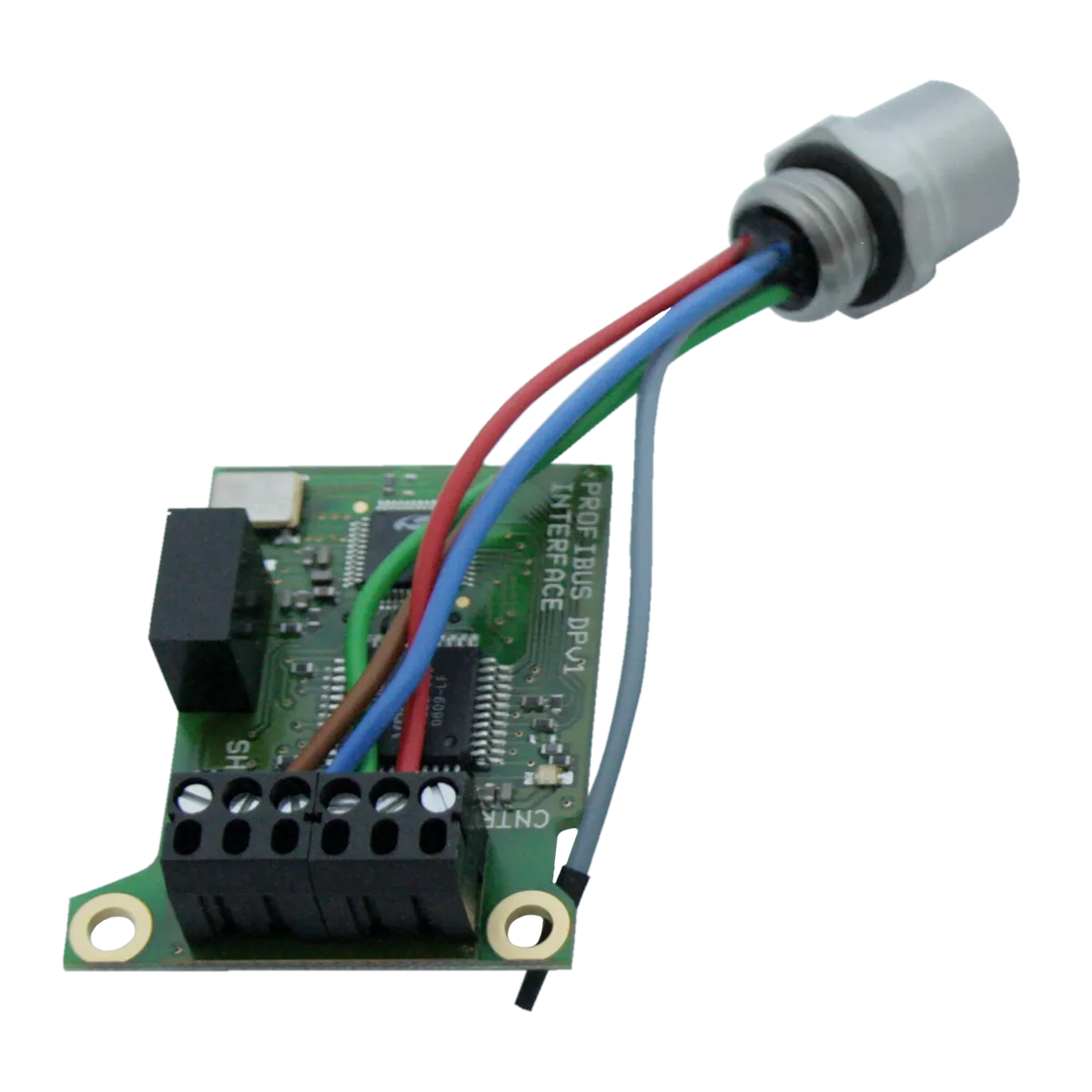

- Profibus DP interface

- Full documentation with GSD files for Siemens PLCs

$340.00

excl. sales taxes, custom tariffs and shipping

Product Description

The Profibus DP interface is a robust fieldbus protocol used in automation for efficient data exchange. Operating on the RS-485 standard, it supports high-speed transfer up to 12 Mbps and can connect up to 126 devices. The Profibus DP interface ensures seamless integration with Optris CT, CTlaser, or CTratio pyrometers, allowing real-time control and diagnostics. It supports synchronization, parameterization, and alarm handling, ideal for complex industrial applications.

- Profibus DP interface

- Full documentation with GSD files for Siemens PLCs

Specification

General Specifications

Environmental rating: IP67 (Nema-4) (when installed)

Operating temperature: -20 °C to 80 °C (-4 °F to 176 °F)

Relative humidity: 10 – 95 %, non-condensing

Interface Board Characteristics

Port Protocol: Profibus DP

Transfer speed: up to 12Mbit/s

Connector: 1 x M12 Profibus socket 5 pin B-coded

Physical layer: RS485 (2-wire), line, Master/ slave system

Maximal number of devices in network: Up to 126 slave devices

Downloads

FAQs

Where are the communication commands for the Profibus interface?

Please review the documentation. The manual publishes the communication commands.

How do I install the Profibus interface?

Install the M12 device socket on the lower left and the cable connection on the upper left of the CT box. Plug the interface into the intended slot next to the display, secure it with the supplied screws, and connect the device socket with the screw terminal on the interface.

How is the Profibus address set on the optris CT?

After mounting the interface, supply power to the optris CT, press the MODE button until “SL001” appears, and use the UP and DOWN buttons to select the desired slave address. This address will be set after six seconds. Power off the optris CT for three seconds to complete the process.

How does data conversion work with the Profibus interface?

The cyclic data received for object temperature and internal sensing head temperature is in 2-byte hex format, with the high byte first. Convert the hex format to decimal, subtract 1000, and divide by 10 to get the temperature in °C.

How does the Profibus DP system operate?

In a Profibus DP system, the master (e.g., PLC or PC) communicates with multiple slaves (e.g., IO devices or drives). Only the master can initiate communication, while slaves respond to master requests. The system involves parameter data, configuration data, and diagnostic data exchanges during startup and cyclic data transfer during operation.

What is the purpose of the GSD file?

The GSD (Generic Station Description) file defines the device characteristics and must be read into the PROFIBUS configuration tool (e.g., SIMATIC MANAGER) to set up communication between the master and the optris CT with the interface.

Scope of Supply

- 1x Profibus DP interface

- 1x M12 device socket

- 1x Cable connection M12x1,5

- 2x Screws M3x5

- 1x USB stick (operators manual, GSD file)

- 1x Quick reference

Talk to us about your IR Temperature Measurement Requirements

Our Infrared Temperature Measurement experts can help you find the right Optris product for your application.