Modbus RTU interface board

The Modbus RTU interface, used for CT, CTlaser, and CTRatio pyrometers, is ideal for industrial infrared temperature monitoring.

- Modbus RTU interface for CT, CTlaser, and CTRatio pyrometers

- Robust communication standard for industrial use

- 1200 m (3937 ft) range

- Reliable data transmission

$80.00

excl. sales taxes, custom tariffs and shipping

Product Description

The Modbus RTU interface, used for CT, CTlaser, and CTRatio pyrometers, is ideal for industrial infrared temperature monitoring. It operates over two wires (A and B) with differential signaling for noise immunity, supporting up to 32 devices over 1200 m (3937 ft). Typical baud rates are 9600 or 19200. Proper 120-ohm termination ensures reliable data transmission for precise infrared temperature readings.

- Modbus RTU interface for CT, CTlaser, and CTRatio pyrometers

- Robust communication standard for industrial use

- 1200 m (3937 ft) range

- Reliable data transmission

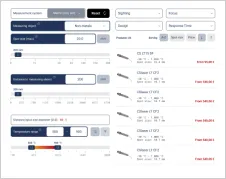

Specification

General Specifications

Environmental rating: IP67 (Nema-4) (when installed)

Operating temperature: -20 °C to 80 °C (-4 °F to 176 °F)

Relative humidity: 10 – 95 %, non-condensing

Interface Board Characteristics

Port Protocol: Modbus RTU

Transfer speed: up to 19200 bps

Connector: none

Physical layer: RS485 (2-wire), line, Master/slave system

Maximal number of devices in network: Up to 32 devices

Serial interface parameters

Baud rate: 9600 or 19200, set by user (factory default: 9600)

Data bits: 8

Parity: even

Stop bits: 1

Flow control: off

FAQs

What is the difference between Modbus RTU, based on an RS485 physical layer, and RS485?

RS485 is a physical layer standard for serial communication, defining the electrical characteristics of the drivers and receivers. It supports balanced transmission, allowing for reliable data exchange over long distances and through noisy environments. RS485 specifies the physical connection, voltage levels, and cable characteristics but does not define the data format or protocol used for communication.

Modbus RTU, on the other hand, is a communication protocol that operates on the RS485 physical layer. It defines the structure of the messages, including how data is packaged, addressed, and error-checked. While RS485 provides the means for data transmission, Modbus RTU specifies the rules for data communication, enabling devices from different manufacturers to communicate over an RS485 network using a standardized set of commands and data formats. Essentially, RS485 is the hardware layer, and Modbus RTU is the software layer that dictates how data is transmitted and interpreted on that hardware.

What is the difference between Modbus RTU and other communication protocols for infrared pyrometers?

Modbus RTU is a robust communication standard that supports long-distance and multi-device communication with high noise immunity, which is ideal for industrial environments. It operates at baud rates of 9600 or 19200, suitable for precise and efficient data transmission.

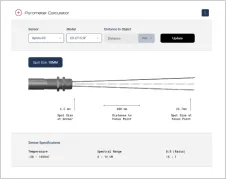

How is the Modbus RTU interface installed on a CT device?

The Modbus RTU interface board is plugged into the designated slot beside the display and secured with M3x5 screws. Connections are made by matching terminal A to A and B to B on the devices.

What is the purpose of the 120-ohm termination resistor?

The 120-ohm termination resistor is used at the last device in the Modbus network to prevent signal reflections and ensure reliable communication.

How are device addresses managed in a Modbus network?

Each device on the Modbus bus requires a unique address, which can be set using the device interface or communication commands. Addresses range from 1 to 247.

What protocol does the Modbus RTU interface use for communication?

The Modbus RTU interface uses the Modbus protocol for communication, ensuring fast data transfer without additional overhead bytes.

How do you change the baud rate for the Modbus RTU interface?

The baud rate can be adjusted via the device interface to match the required communication speed.

What happens if multiple devices on the Modbus bus try to communicate simultaneously?

In Modbus networks, devices are slaves and cannot communicate simultaneously. Commands are broadcast to all devices, but only the addressed device responds.

Scope of Supply

- 1x Modbus RTU interface board

- 1x M12 cable gland

- 1x Set of Mounting screws, cable tie

- 1x Quick reference

Talk to us about your IR Temperature Measurement Requirements

Our Infrared Temperature Measurement experts can help you find the right Optris product for your application.