Xi 400 CM

The Xi 400 CM infrared package includes a Xi 400 infrared imager, a visible camera, and a USB server, all pre-assembled in an outdoor housing with a wall mount.

- Dedicated to outdoor condition monitoring and fire detection

- IR camera with 382 x 288 pixels

- HD VIS camera with 1280 x 720 pixels

- USB-Server Gigabit (PoE) for easy integration of both cameras

- Environmental rating IP66

$4,825.00

excl. sales taxes, custom tariffs and shipping

Product Description

Early fire detection and emergency fire planning can be challenging in outdoor locations such as paper mills, sawmills, biomass power plants, scrap metal and waste recycling plants, and other large facilities where fire risks are prevalent. Fire causes significant financial loss annually due to inadequate early detection systems. Infrared cameras are particularly effective for monitoring extensive areas and providing early fire warnings, which are crucial for executing fire emergency action plans.

In numerous industrial environments, monitoring equipment and detecting early fire signs are crucial, especially in extreme temperature conditions. For example, conveyor systems transporting coal or wood chips are often found in cold climates. The bearings in these systems can overheat, risking conveyor malfunction and elevating the fire hazard. Similarly, the friction in wood chip processes can generate small sparks, potentially igniting fires in wood pulp operations. Furthermore, large, damp piles of decomposing mulch, wood pulp, or other biomass materials can spontaneously combust, posing significant dangers to nearby factories or residential areas.

The Xi 400CM Package meets the critical need for continuous monitoring in industrial outdoor settings. This comprehensive package incorporates all necessary components to effectively monitor equipment and fire hazards, offering early warnings when equipment overheats or when ignition temperatures signal the onset of a fire. The package features an infrared camera, an outdoor enclosure equipped with a fan and heating element, a front window air purge, a high-definition video camera, and a USB Gigabit Server for long-distance video transmission.

By consolidating these elements into a single standardized package, the Xi 400 CM Package can be offered at an affordable price, resulting in substantial savings compared to custom installations. Enhanced fire safety is achieved by monitoring more areas from multiple mounting locations. The cost-effective nature of this system supports comprehensive area coverage, providing more effective early fire detection solutions.

Central to the Xi 400CM Package’s detection strategy is the utilization of every pixel in the high-resolution 382 x 288 infrared camera to identify hot spots. The high-speed processors within the Xi 400 thermal imager continuously scan the field of view for hot spots that exceed user-defined temperature thresholds. The Xi 400 infrared camera includes a process interface port capable of sending alarm signals (0/4-20 analog output) to external control devices or sprinkler systems. Additional process interface modules can be incorporated to set fire alarm temperatures in various locations within the camera’s field of view, enhancing the system’s ability to detect and respond to potential fire hazards.

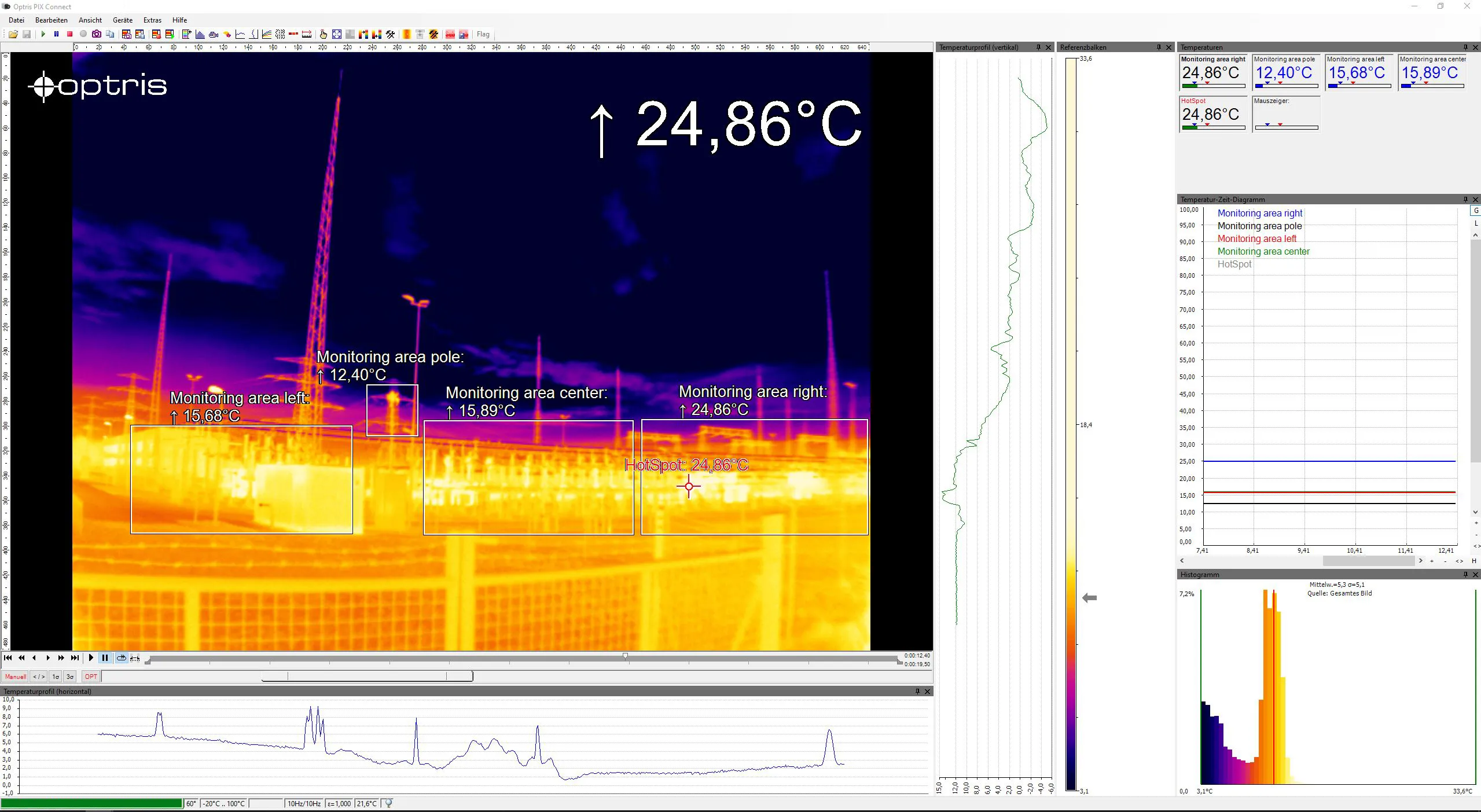

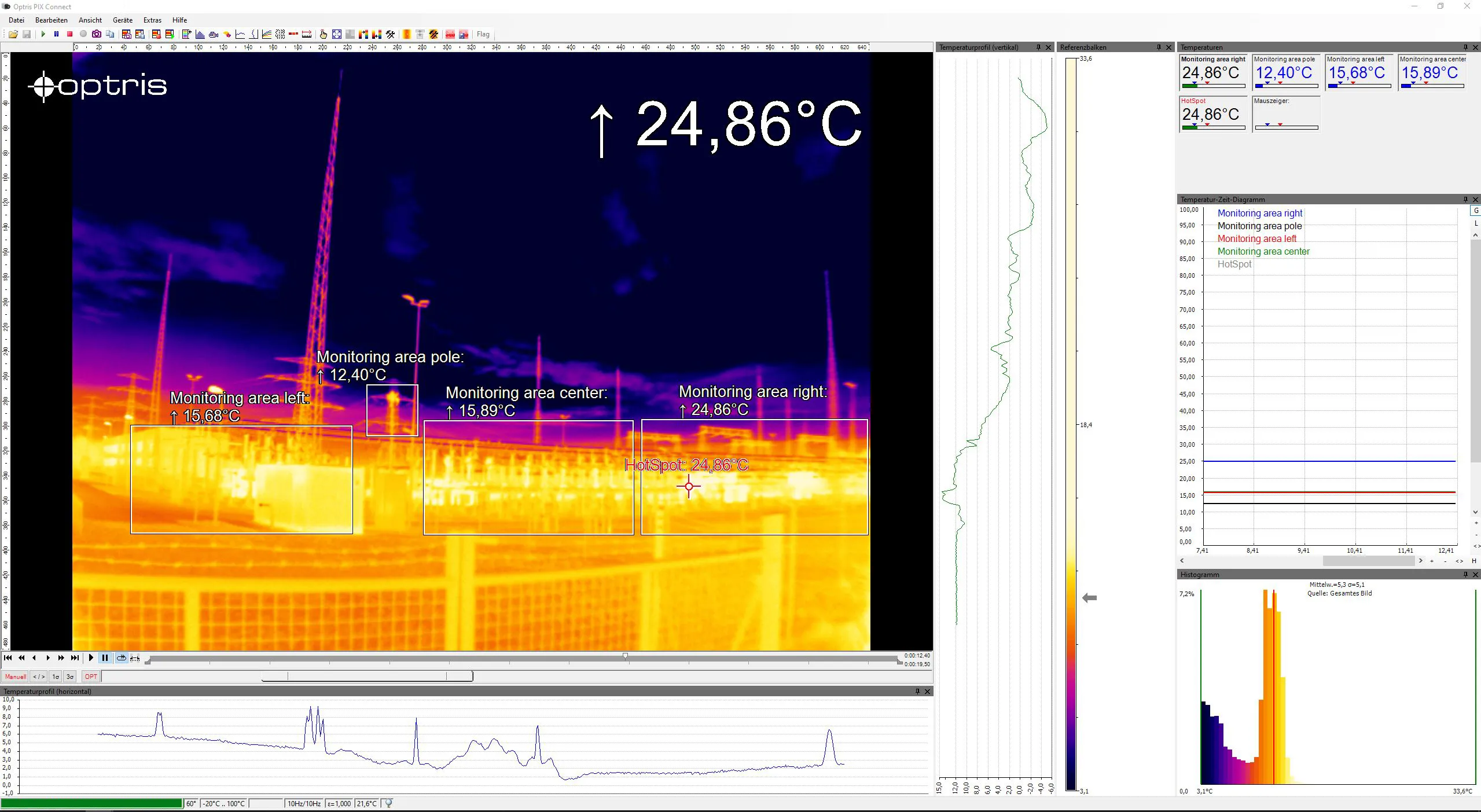

The system also supports transmitting high-resolution thermal and video images to a control room PC equipped with PIX Connect Software. This software can be configured to display multiple images from various mounting locations, providing real-time thermal video reviews to identify false positives, such as excavator exhaust pipes or solar reflections on shiny metal surfaces. This feature is crucial in preventing unnecessary activation of fire control systems or emergency evacuations.

Engineered and manufactured in Germany, the Xi 400CM Package offers a comprehensive and affordable early fire detection solution. Engineers worldwide are available to assist with installation questions, ensuring that the system is effectively implemented and operational in various industrial settings.

Early fire detection and emergency fire planning can be challenging in outdoor locations such as paper mills, sawmills, biomass power plants, scrap metal and waste recycling plants, and other large facilities where fire risks are prevalent. Fire causes significant financial loss annually due to inadequate early detection systems. Infrared cameras are particularly effective for monitoring extensive areas and providing early fire warnings, which are crucial for executing fire emergency action plans.

In numerous industrial environments, monitoring equipment and detecting early fire signs are crucial, especially in extreme temperature conditions. For example, conveyor systems transporting coal or wood chips are often found in cold climates. The bearings in these systems can overheat, risking conveyor malfunction and elevating the fire hazard. Similarly, the friction in wood chip processes can generate small sparks, potentially igniting fires in wood pulp operations. Furthermore, large, damp piles of decomposing mulch, wood pulp, or other biomass materials can spontaneously combust, posing significant dangers to nearby factories or residential areas.

The Xi 400CM Package meets the critical need for continuous monitoring in industrial outdoor settings. This comprehensive package incorporates all necessary components to effectively monitor equipment and fire hazards, offering early warnings when equipment overheats or when ignition temperatures signal the onset of a fire. The package features an infrared camera, an outdoor enclosure equipped with a fan and heating element, a front window air purge, a high-definition video camera, and a USB Gigabit Server for long-distance video transmission.

By consolidating these elements into a single standardized package, the Xi 400 CM Package can be offered at an affordable price, resulting in substantial savings compared to custom installations. Enhanced fire safety is achieved by monitoring more areas from multiple mounting locations. The cost-effective nature of this system supports comprehensive area coverage, providing more effective early fire detection solutions.

Central to the Xi 400CM Package’s detection strategy is the utilization of every pixel in the high-resolution 382 x 288 infrared camera to identify hot spots. The high-speed processors within the Xi 400 thermal imager continuously scan the field of view for hot spots that exceed user-defined temperature thresholds. The Xi 400 infrared camera includes a process interface port capable of sending alarm signals (0/4-20 analog output) to external control devices or sprinkler systems. Additional process interface modules can be incorporated to set fire alarm temperatures in various locations within the camera’s field of view, enhancing the system’s ability to detect and respond to potential fire hazards.

The system also supports transmitting high-resolution thermal and video images to a control room PC equipped with PIX Connect Software. This software can be configured to display multiple images from various mounting locations, providing real-time thermal video reviews to identify false positives, such as excavator exhaust pipes or solar reflections on shiny metal surfaces. This feature is crucial in preventing unnecessary activation of fire control systems or emergency evacuations.

Engineered and manufactured in Germany, the Xi 400CM Package offers a comprehensive and affordable early fire detection solution. Engineers worldwide are available to assist with installation questions, ensuring that the system is effectively implemented and operational in various industrial settings.

Specification

| MODEL | Xi 400 LT 18°x14° CM | Xi 400 LT 29°x22° CM | Xi 400 LT 53°x38° CM | Xi 400 LT 80°x54° CM |

| DETECTOR | ||||

| Optical resolution | 382 x 288 pixels | |||

| Pixel pitch | 17 µm | |||

| Detector | Uncooled bolometer | |||

| Spectral range | LT: 8 µm – 14 µm | |||

| Optical Filter | Optional: CO2 10.6 µm | |||

| Frame rate | 80 Hz / 27 Hz | |||

| OPTICAL | ||||

| Field of View | 18°x14° | 29°x22° | 53°x38° | 80°x54° |

| Focal length [mm] | 20 mm | 12.7 mm | 7.7 mm | 5.7 mm |

| F Number | 1.1 | 0.9 | 0.9 | 0.9 |

| Optical Resolution | 190:1 | 250:1 | 150:1 | 110:1 |

| Minimum Distance to target | 350 mm (13.8 in) | 350 mm (13.8 in) | 250 mm (9.8 in) | 200 mm (7.9 in) |

| Interchangeable optics | No | |||

| MEASUREMENT | ||||

| Object Measurement Range | -20 °C … 100 °C (-4 °F … 212 °F)

0 °C … 250 °C (32 °F … 482 °F) (20) 150 °C … 900 °C **1) (302 ° F … 1652 °F*1) optional: 200 °C … 1500 °C **2) (392 °F … 2732 °F*2) |

|||

| Accuracy *1) | ±2 °C or ±2 % (±3.6 °F or ±2 %), whichever is greater | |||

| Thermal Sensitivity (NETD) *2) | 50mK | |||

| Smallest detectable Spot Size IFOV: 1 pixel | 0.3 mm | 0.5 mm | 0.7 mm | 0.8 mm |

| Smallest measurable Spot Size MFOV | 0.9 mm | 1.5 mm | 2.1 mm | 2.4 mm |

| Measurement Field of View (MFOV) | 3 x 3 pixels | |||

| Warm-up time | 10 min | |||

| Emissivity /Transmissivity/ Reflectivity | adjustable: 0.100…1.100 | |||

| INTERFACES | ||||

| Interface | Ethernet over USB GigE (PoE) interface | |||

| Supported Protocols | Ethernet (max. 1000 Mbit/s) | |||

| Compatible Software | PIXConnect, ConnectSDK, EasyAPI, DirectSDK | |||

| ANALOG INPUT/OUTPUT | ||||

| Direct output/input | 1x analog output (0/4-20 mA) 1x input (analog or digital); optically isolated |

|||

| Optional Industrial Process interface (PIF) | 2x 0 – 10 V input, digital input (max. 24 V), 3x 0/4 – 20 mA outputs, 3x relay (0 – 30 V/ 400 mA), fail-safe relay |

|||

| Cable length | Ethernet / RS485: 20 m (66 ft), extendable up to 100 m (328 ft) | |||

| IMAGE PROCESSING | ||||

| Configuration | via PIXConnect | |||

| Operation | computer-enabled | |||

| Capabilities | For high ambient Temperatures, very good noise suppression, Measure Areas of Interest, Linescanner, EventGrabber, Merger, Alarming, Comparison Functions, Temperature-Time Diagrams, Temperature Profiles, Recording & Playing, Triggering … | |||

| GENERAL | ||||

| Size | 485 mm x 140 mm x 265 mm (19.1 in x 5.5 in x 10.4 in) | |||

| Housing Material | Aluminum | |||

| Weight | 2 kg / 2.5 kg (4.4 Lb / 5.5 Lb) with wall mount bracket | |||

| Tripod | wall mount | |||

| Focus | Motorized | |||

| Country of Origin | Germany | |||

| ENVIRONMENTAL & CERTIFICATIONS | ||||

| Operating Temperature Range | -40 °C … 50 °C (-40 °F … 122 °F) | |||

| Storage Temperature Range | -40 °C … 70 °C (-40 °F … 158 °F) | |||

| Relative humidity | 10 – 95 %, non-condensing | |||

| Protection Class | IP 66 | |||

| EMC | 2014/30/EU | |||

| Shock | IEC 60068-2-27 (25 G and 50 G) | |||

| Vibration | IEC 60068-2-6 (sinus shaped) IEC 60068-2-64 (broadband noise) |

|||

| Standards | CE, UKCA, RoHS | |||

| POWER | ||||

| Power Supply | 24 VDC or PoE | |||

| Current Draw | 3 A (short term: 6 A) | |||

| Power Consumption | 70W | |||

| VISUAL CAMERA (optional) | ||||

| Optical resolution | 1280 x 720 pixels | |||

| Frame rate | 30 Hz | |||

| Lens size | 1/4″ | |||

| FOV | 65° (DFOV) | |||

| Type | IP camera | |||

| Protocol | FFMPEG (H264), RTSP, TCP | |||

| AIR PURGE & HEATING | ||||

| Air purge collar | Integrated | |||

| Air pressure | Absolute pressure 1.1 bar at 20 – 100 l/min | |||

| Heating | PTC heater (starts automatically at T < 59 °F) / Fan for homogeneous temperature distribution |

|||

| Part number | OPTXI40LTCMF20T090 | OPTXI40LTCMF13T090 | OPTXI40LTCMF08T090 | OPTXI40LTCMF06T090 |

| Additional Remarks | 1) Accuracy statement effective from 150 °C (302 °F) 2) If this option is ordered the (20) 150 °C … 900 °C (302 °F … 1652 °F) range is not available 3) Measurement of noise equivalent temperature difference (NETD) according to VDI 5585, method B, 25 °C (77 °F) black body temperature -20 °C … 100 °C (-4 °F … 212 °F) temperature range, frame rate at 20Hz |

|||

Areas of Application

Software

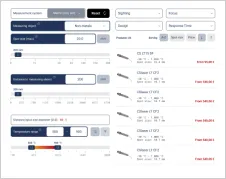

Thermography software optris PIX Connect is included and license-free.All infrared cameras are delivered with the thermography software optris PIX Connect, developed specifically for the extensive documentation and analysis of thermal images. The Windows-based PIX Connect software enables users to tailor the infrared cameras to meet specific requirements. It analyses live and recorded temperature data and triggers alarm signals for process integration.The key to leveraging the Optris infrared camera is a correct configuration. This includes detailed device-specific configurations such as frame rate, measurement range adjustments, external communication settings, and USB/Ethernet configurations. Moreover, PIX Connect facilitates firmware updates and the download of configuration files over the Internet.

PIX Connect

Thermography software optris PIX Connect is included and license-free.All infrared cameras are delivered with the thermography software optris PIX Connect, developed specifically for the extensive documentation and analysis of thermal images. The Windows-based PIX Connect software enables users to tailor the infrared cameras to meet specific requirements. It analyses live and recorded temperature data and triggers alarm signals for process integration.The key to leveraging the Optris infrared camera is a correct configuration. This includes detailed device-specific configurations such as frame rate, measurement range adjustments, external communication settings, and USB/Ethernet configurations. Moreover, PIX Connect facilitates firmware updates and the download of configuration files over the Internet.

PIX Connect

Optris offers several different SDKs for our Xi and PI thermal imaging cameras. Depending on the operating platform, the infrared camera, the coding language, and the hardware platform, different software interfaces can be utilized:

SDK

Optris offers several different SDKs for our Xi and PI thermal imaging cameras. Depending on the operating platform, the infrared camera, the coding language, and the hardware platform, different software interfaces can be utilized:

SDK

The Optris IRmobile allows users to set up and commission an Optris infrared pyrometer or infrared camera with an Android smartphone or tablet. This tool becomes handy for commissioning and aligning the infrared camera’s field of view or adjusting the configuration. The app analyzes the connected infrared camera’s live infrared image stream with auto hot and cold spot detection. For pyrometers, a temperature-time diagram or the video signal is displayed. This app works on most Android devices running 5.0+ with a USB port supporting USB-OTG (On The Go).

Google Play

The Optris IRmobile allows users to set up and commission an Optris infrared pyrometer or infrared camera with an Android smartphone or tablet. This tool becomes handy for commissioning and aligning the infrared camera’s field of view or adjusting the configuration. The app analyzes the connected infrared camera’s live infrared image stream with auto hot and cold spot detection. For pyrometers, a temperature-time diagram or the video signal is displayed. This app works on most Android devices running 5.0+ with a USB port supporting USB-OTG (On The Go).

Google Play

Thermography software optris PIX Connect is included and license-free.All infrared cameras are delivered with the thermography software optris PIX Connect, developed specifically for the extensive documentation and analysis of thermal images. The Windows-based PIX Connect software enables users to tailor the infrared cameras to meet specific requirements. It analyses live and recorded temperature data and triggers alarm signals for process integration.The key to leveraging the Optris infrared camera is a correct configuration. This includes detailed device-specific configurations such as frame rate, measurement range adjustments, external communication settings, and USB/Ethernet configurations. Moreover, PIX Connect facilitates firmware updates and the download of configuration files over the Internet.

PIX Connect

Thermography software optris PIX Connect is included and license-free.All infrared cameras are delivered with the thermography software optris PIX Connect, developed specifically for the extensive documentation and analysis of thermal images. The Windows-based PIX Connect software enables users to tailor the infrared cameras to meet specific requirements. It analyses live and recorded temperature data and triggers alarm signals for process integration.The key to leveraging the Optris infrared camera is a correct configuration. This includes detailed device-specific configurations such as frame rate, measurement range adjustments, external communication settings, and USB/Ethernet configurations. Moreover, PIX Connect facilitates firmware updates and the download of configuration files over the Internet.

PIX Connect

Optris offers several different SDKs for our Xi and PI thermal imaging cameras. Depending on the operating platform, the infrared camera, the coding language, and the hardware platform, different software interfaces can be utilized:

SDK

Optris offers several different SDKs for our Xi and PI thermal imaging cameras. Depending on the operating platform, the infrared camera, the coding language, and the hardware platform, different software interfaces can be utilized:

SDK

The Optris IRmobile allows users to set up and commission an Optris infrared pyrometer or infrared camera with an Android smartphone or tablet. This tool becomes handy for commissioning and aligning the infrared camera’s field of view or adjusting the configuration. The app analyzes the connected infrared camera’s live infrared image stream with auto hot and cold spot detection. For pyrometers, a temperature-time diagram or the video signal is displayed. This app works on most Android devices running 5.0+ with a USB port supporting USB-OTG (On The Go).

Google Play

The Optris IRmobile allows users to set up and commission an Optris infrared pyrometer or infrared camera with an Android smartphone or tablet. This tool becomes handy for commissioning and aligning the infrared camera’s field of view or adjusting the configuration. The app analyzes the connected infrared camera’s live infrared image stream with auto hot and cold spot detection. For pyrometers, a temperature-time diagram or the video signal is displayed. This app works on most Android devices running 5.0+ with a USB port supporting USB-OTG (On The Go).

Google Play

Downloads

DATASHEET

PDF - 715.78 KB

Xi 400 CM Datasheet (US)

Complete the form to download the file

FAQs

Is temperature measurement important for infrared camera early fire detection systems?

Yes, particularly when automatic alarming is a requirement. In some markets, accreditation bodies are establishing requirements for temperature measurement capabilities which accurately signal temperature increases of 20 °C (68 °F).

Can I just use a thermal security imager and alarm on the hot spots?

While it may be easy for thermal imagers developed for security applications to identify a hot spot on an image, it can be more challenging for cameras not designed to measure temperature to deliver alarms on a series of targets that may each have their own unique temperature alarm thresholds. Because some potential areas of ignition will get warm before they ignite, it may be prudent in some cases to establish lower alarm or “pre-alarm” temperature thresholds. A camera designed and calibrated to deliver accurate temperature measurements on ambient temperature targets may be a better solution when even subtle temperature increases can signal a potential fire threat.

Is infrared camera resolution important?

Almost always. Most infrared cameras can be programmed to deliver an alarm when a pixel or grouping of pixels has exceeded a user set threshold. If the target to be monitored (i.e. small wood chip) is very hot but comprises only a portion of the thermal imager pixel, the camera will report a temperature measurement that is the average of the wood chip temperature and the surrounding ambient temperatures.

When will a lower resolution and more affordable infrared camera work for a given application?

When the spot size to be monitored is the same size of a pixel or group of pixels. An example may be a measurement on the side of a large furnace where it is important to understand the average temperature but not necessary to measure a small spot on the furnace wall.

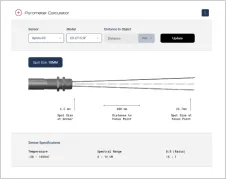

How do I know the pixel is too large for an accurate measurement?

Infrared camera suppliers who make thermal imagers for temperature measurement will typically host a spot size calculator on their web site. The calculator should present the geometric size of a single pixel (IFOV) when the camera, the optics and the distance from the target are input into the calculator.

Will a single pixel or IFOV always be large enough for an IR camera to deliver a measurement consistent with the camera specification?

No. While it is possible to detect a temperature increase with a single pixel, all infrared cameras need more than one pixel to measure temperatures accurately. A 3 x 3 pixel matrix has been used as a rule of thumb to define the pixel coverage necessary for a measurement compliant with specified camera accuracy, but this can vary significantly depending on the camera and the infrared detector pitch (size). To determine the true Measurement Field of View (MFOV), use the Optris Optics Calculator or check with the manufacturer to determine MFOV.

I have used handheld cameras to measure temperatures of important mechanical and electrical equipment in my facility. Can I use the XI 400 system for these applications?

Yes. Many facilities are using fixed install infrared cameras to monitor critical electrical and mechanical systems to reduce manpower and provide more comprehensive temperature data. Infrared temperature measurements on transformers, fuses, cable trays, rotating equipment, power cables, motor control centers and switch gear are routinely measured with infrared cameras and can be measured with properly calibrated fixed install infrared cameras as well.In the U.S., the NFPA 70B-2023 Standard for Electrical maintenance covers important details about using infrared equipment to monitor these systems and is an excellent guide for any company or facility interested in establishing an internal standard for electrical equipment maintenance. The document references the importance of properly calibrated infrared camera equipment and the use of comparative thermography and small temperature rise as an indicator of equipment health or future fire hazard.The Xi 400 is developed and produced in Germany and is calibrated according to government standards. Calibration certificates are available for customers requiring traceability on calibration standards.

Does the camera need to be connected to a PC hosting PIX Connect software to identify an alarm condition and transmit an alarm signal?

No. The Xi 400 can operate in autonomous mode and transmit alarm signals when temperatures fall outside of user set thresholds. PIX Connect software (no charge download) is required to set up the alarm conditions.

Do I need PIX Connect software to display the thermal image?

Yes. The ethernet signal produced by the converter housed in the outdoor housing needs to be connected to a standard PC installed with PIX Connect software to produce and display a thermal image. PIX Connect software also enables more extensive temperature measurement functions (dozens of measurement areas, special color palettes for differing temperature conditions, multiple window display for numerous cameras, image merge for large targets, etc.).

How many areas can be monitored without the use of a PC?

One area can be monitored with alarm outputs communicated through the process interface port on the back of the camera. Industrial Process Interface modules can be connected to the same output port providing three analog output signals from three distinct areas. Up to three Industrial Process Interface modules can be connected to the camera housing to produce 9 separate analog alarm signals.

Can I connect Optris Infrared cameras to the Video Management System I use for my security cameras?

The signal produced by the camera and converted to ethernet in the USB converter is not formatted for display on standard video management systems because it includes encoding used by the PIX Connect software to convert each image pixel to a temperature measurement. The use of the processing power in the PC supports measurement and alarming on over 11,000 infrared pixels generated by the Xi 400.

Is temperature measurement important for infrared camera early fire detection systems?

Yes, particularly when automatic alarming is a requirement. In some markets, accreditation bodies are establishing requirements for temperature measurement capabilities which accurately signal temperature increases of 20 °C (68 °F).

Can I just use a thermal security imager and alarm on the hot spots?

While it may be easy for thermal imagers developed for security applications to identify a hot spot on an image, it can be more challenging for cameras not designed to measure temperature to deliver alarms on a series of targets that may each have their own unique temperature alarm thresholds. Because some potential areas of ignition will get warm before they ignite, it may be prudent in some cases to establish lower alarm or “pre-alarm” temperature thresholds. A camera designed and calibrated to deliver accurate temperature measurements on ambient temperature targets may be a better solution when even subtle temperature increases can signal a potential fire threat.

Is infrared camera resolution important?

Almost always. Most infrared cameras can be programmed to deliver an alarm when a pixel or grouping of pixels has exceeded a user set threshold. If the target to be monitored (i.e. small wood chip) is very hot but comprises only a portion of the thermal imager pixel, the camera will report a temperature measurement that is the average of the wood chip temperature and the surrounding ambient temperatures.

When will a lower resolution and more affordable infrared camera work for a given application?

When the spot size to be monitored is the same size of a pixel or group of pixels. An example may be a measurement on the side of a large furnace where it is important to understand the average temperature but not necessary to measure a small spot on the furnace wall.

How do I know the pixel is too large for an accurate measurement?

Infrared camera suppliers who make thermal imagers for temperature measurement will typically host a spot size calculator on their web site. The calculator should present the geometric size of a single pixel (IFOV) when the camera, the optics and the distance from the target are input into the calculator.

Will a single pixel or IFOV always be large enough for an IR camera to deliver a measurement consistent with the camera specification?

No. While it is possible to detect a temperature increase with a single pixel, all infrared cameras need more than one pixel to measure temperatures accurately. A 3 x 3 pixel matrix has been used as a rule of thumb to define the pixel coverage necessary for a measurement compliant with specified camera accuracy, but this can vary significantly depending on the camera and the infrared detector pitch (size). To determine the true Measurement Field of View (MFOV), use the Optris Optics Calculator or check with the manufacturer to determine MFOV.

I have used handheld cameras to measure temperatures of important mechanical and electrical equipment in my facility. Can I use the XI 400 system for these applications?

Yes. Many facilities are using fixed install infrared cameras to monitor critical electrical and mechanical systems to reduce manpower and provide more comprehensive temperature data. Infrared temperature measurements on transformers, fuses, cable trays, rotating equipment, power cables, motor control centers and switch gear are routinely measured with infrared cameras and can be measured with properly calibrated fixed install infrared cameras as well.In the U.S., the NFPA 70B-2023 Standard for Electrical maintenance covers important details about using infrared equipment to monitor these systems and is an excellent guide for any company or facility interested in establishing an internal standard for electrical equipment maintenance. The document references the importance of properly calibrated infrared camera equipment and the use of comparative thermography and small temperature rise as an indicator of equipment health or future fire hazard.The Xi 400 is developed and produced in Germany and is calibrated according to government standards. Calibration certificates are available for customers requiring traceability on calibration standards.

Does the camera need to be connected to a PC hosting PIX Connect software to identify an alarm condition and transmit an alarm signal?

No. The Xi 400 can operate in autonomous mode and transmit alarm signals when temperatures fall outside of user set thresholds. PIX Connect software (no charge download) is required to set up the alarm conditions.

Do I need PIX Connect software to display the thermal image?

Yes. The ethernet signal produced by the converter housed in the outdoor housing needs to be connected to a standard PC installed with PIX Connect software to produce and display a thermal image. PIX Connect software also enables more extensive temperature measurement functions (dozens of measurement areas, special color palettes for differing temperature conditions, multiple window display for numerous cameras, image merge for large targets, etc.).

How many areas can be monitored without the use of a PC?

One area can be monitored with alarm outputs communicated through the process interface port on the back of the camera. Industrial Process Interface modules can be connected to the same output port providing three analog output signals from three distinct areas. Up to three Industrial Process Interface modules can be connected to the camera housing to produce 9 separate analog alarm signals.

Can I connect Optris Infrared cameras to the Video Management System I use for my security cameras?

The signal produced by the camera and converted to ethernet in the USB converter is not formatted for display on standard video management systems because it includes encoding used by the PIX Connect software to convert each image pixel to a temperature measurement. The use of the processing power in the PC supports measurement and alarming on over 11,000 infrared pixels generated by the Xi 400.

Scope of Supply

- Process imager Xi 400

- HD video camera

- Outdoor protective housing

- USB Server Gigabit

- Air purge collar

- Software package optris PIX Connect

- Outdoor Protective Housing Manual

- Process imager Xi 400

- HD video camera

- Outdoor protective housing

- USB Server Gigabit

- Air purge collar

- Software package optris PIX Connect

- Outdoor Protective Housing Manual

Related Products

Talk to us about your IR Temperature Measurement Requirements

Our Infrared Temperature Measurement experts can help you find the right Optris product for your application.