The Essential Role of Temperature Measurement in Accurate Solar Cell Flash Testing

Using Optris High Sensitivity Infrared Pyrometers to Minimize Performance Uncertainty in Solar Flash Tests

Temperature’s Impact on Solar Cell Performance and Solar Flash Testing

Solar Flash Tests, or Sun Simulator Tests, are standard procedures manufacturers use to measure the output performance of solar modules after manufacturing, according to the standard International Electrotechnical Commission (IEC) 61215. These quality tests ensure that each photovoltaic (PV) module meets quality standards and operates effectively.

The disadvantage of sunlight test systems with permanent light is that they heat the solar cell sample under the light during the test, changing the environmental conditions (mainly temperature) of measurements. The main advantage of pulsed solar simulators is that there is no temperature increase in the tested sample.

A solar flash test simulates sunlight to measure the electrical characteristics of solar cells under standardized conditions. By verifying the performance, only cells meeting quality standards are integrated into modules. Additionally, flashers measure the efficiency of each solar cell, which is essential for evaluating overall performance.

As an end-of-line test, the solar cell flash test involves applying a high-intensity flash of light to the solar panel and measuring the response regarding voltage and current. During such a flash test, the PV module is exposed to a short but bright ( 1…100 ms, 10…100 mW/cm^2) flash of light from a xenon-filled arc lamp, metal halide lamps, or LEDs. The output light spectrum of this lamp shall closely match the sun’s spectrum. The functionality of a sun simulator with a flash lamp relies on precise synchronization between the flash and the acquisition system due to the light pulse’s specific decay characteristics. An exponential decay can introduce significant errors if there is uncertainty in the acquisition delay. To minimize this error, measurements must be repeated and averaged.

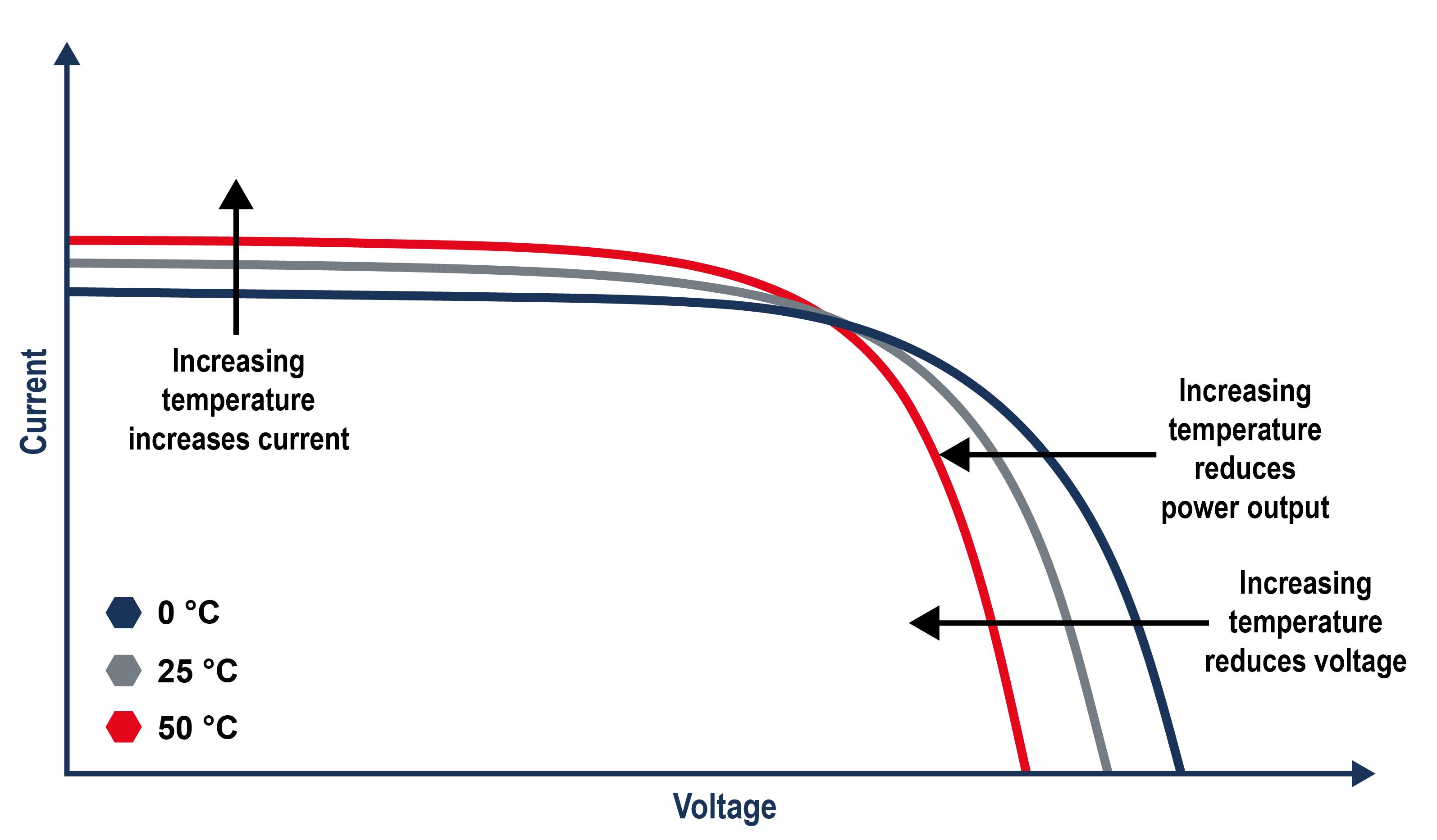

The amount and intensity of solar insolation (solar irradiance) control the PV array’s output current (I). In contrast, the operating temperature of the solar cells affects the output voltage (V). Higher solar radiation increases the current (I), whereas rising cell temperatures decrease the voltage (V).

The measured characteristic current-voltage I-V curve is used to determine the panel’s efficiency and health, identify performance issues, and ensure that it functions within its specified operating range.

A flash test provides the following information about a solar panel: open-circuit voltage, short-circuit current, maximum power point, and panel efficiency.

The open-circuit voltage represents the maximum voltage the panel can produce with no current flowing. The short-circuit current indicates the maximum current the panel can produce with no voltage across it. The maximum power point combines voltage and current at which the solar panel generates its highest power output. Panel efficiency measures how effectively the panel converts sunlight into electrical energy.

Nevertheless, the temperature significantly impacts solar cell performance. As temperature increases, the bandgap of the semiconductor material reduces, decreasing the energy needed to break the bonds. This results in lower open-circuit voltage and, consequently, reduced energy production. Conversely, lower temperatures decrease resistance, increasing energy production. As the temperature of the solar cell increases, its voltage decreases, reducing the panel’s overall power output. Therefore, for such a test, the exact temperature of the solar cell surface shall be recorded. The results are crucial for calibration, certification, and ensuring compliance with rigorous international standards, providing reassurance about the quality of the product.

To measure the performance of each solar cell correctly, the temperature-related I-V characteristic must be recorded with the solar cell’s surface temperature.

Precision I-V Diagrams: Ensuring Accurate Temperature Measurement in Solar Cell Performance Testing

The objective of this setup is to record the precise I-V diagram for mass-produced solar cells at the exact surface temperature of the solar cells. The output of a pure xenon short-arc lamp provides a continuous spectral power distribution with a color temperature of about 5500 to 6200K, covering a light spectrum range from 200 nm to 1200 nm.

The temperature of the solar cell during testing is typically around room temperature, with the optimal temperature for solar panels being approximately 25 °C (77 °F). For every degree above 25 °C (77 °F), a solar panel’s output can decrease by about 0.5%, affecting overall energy production.

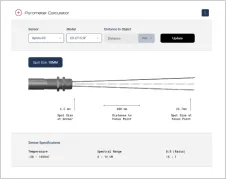

Using a short-wavelength infrared sensor in the same spectral range as the light emission may not be feasible due to possible crosstalk issues and the relatively low-temperature range. Therefore, a conventional infrared pyrometer with LT wavelength is an optimal candidate.

For accurate temperature referencing during the solar flash test, the precision of a single point is usually sufficient. The infrared sensor must react quickly due to the brief flashing moment, requiring fast signal integration and response time. The temperature must be measured precisely when the flasher illuminates the cell.

The Optris CS Laser LT is the ideal tool for this task, providing the necessary precision and reliability. It allows for measuring even slight temperature differences from 0.025 °C (32 °F) onwards, which is crucial for continuously monitoring product homogeneities. The system accuracy at ambient temperature is ±1% or ±1 C, whichever is greater. The contactless thermometer demonstrates exceptional repeatability, with only ±0.3% or ±0.3 °C at ambient temperatures of 23 ± 5 °C and target temperatures above 20 °C (68 °F).

Reducing Uncertainty in Solar Cell Performance Testing with Optris High Sensitivity Pyrometers

Precise temperature measurements ensure that the I-V curves accurately reflect the true performance of the solar cells under specific conditions. Any deviation in temperature can lead to incorrect assessments of the cell’s efficiency and output. As temperature influences the open-circuit voltage and the maximum power point, maintaining accurate temperature control and measurement allows for reliable and consistent evaluation of solar cell performance. This precision is essential for optimizing production processes, ensuring product quality, and predicting solar modules’ performance and reliability.

As the I-V diagrams of solar cells are temperature dependent, Optris pyrometers with high-sensitivity features and accuracy are necessary to evaluate the performance correctly. Solar cell performance end-of-line certifications would otherwise have to include considerable uncertainty due to possible temperature effects. To optimistic interpretation of the data could result in underpowered solar modules and insufficient power output, and to pessimistic interpretation of the data could result in weak advertised solar cell performance.

Next to accuracy, mechanical integration is also essential. The space inside the cell flasher is limited. The compact product design and mounting brackets help to place the sensor correctly and aim it in the right direction.

Recommended Products

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.