Accurate Non-contact Temperature Measurement in Glass Tempering Line

Ensuring Uniform Heating and Cooling in Low Emissivity Glass Toughening with Precise Temperature Control

Thermal Tempering for Strengthening and Protecting Glass Relies on Precise Temperature Control

Thermal tempering is one of the processes regularly used by many companies in this industry. It is used in areas such as glass finishing, glass construction, safety glass, and glass design. The thermal tempering of toughened safety glass, often referred to as hardening, increases the bending strength of the glass panes treated in this way to values that can exceed 200 N/mm².

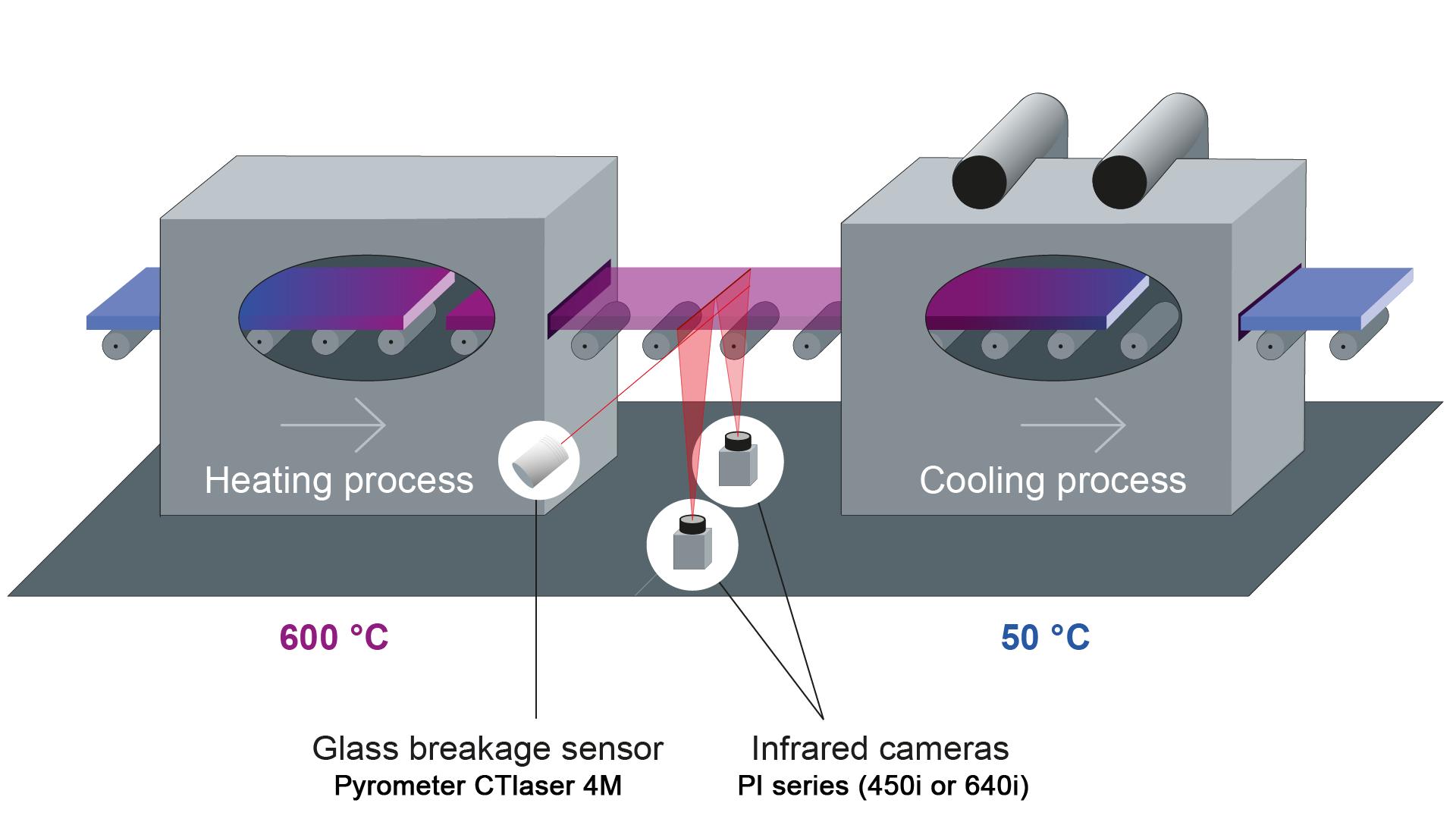

This thermal treatment increases the thermal shock resistance of the glass panes. During thermal toughening, a furnace first heats the glass pane above the transformation point to around 620 °C to 670 °C (1148 °F to 1238 °F). The surface is then cooled very quickly. This is usually done by blowing cool air into the cooling section. The entire process is highly dependent on the temperature of the glass pane being evenly above the transformation point when cooling begins. If this is not the case, excessive tensile stresses within the glass can cause the pane to break. Whether the entire surface is at the correct temperature during the heating process cannot be determined without IR measurement.

Conventionally, tempered glass has been measured with pyrometers or infrared linescanners from above. This has the drawback that glass with a low emissivity coating is highly reflective in the infrared. Therefore, traditional measurement approaches with pyrometers or line scanners above the production line will pick up the wrong temperature. Additionally, the ambient temperature above the exit of the tempering furnace often exceeds the operating temperature of the installed equipment, which limits the use case, lowers temperature accuracy, and complicates installation.

Overcoming Measurement Difficulties in Thermal Tempering of Tempered Glass

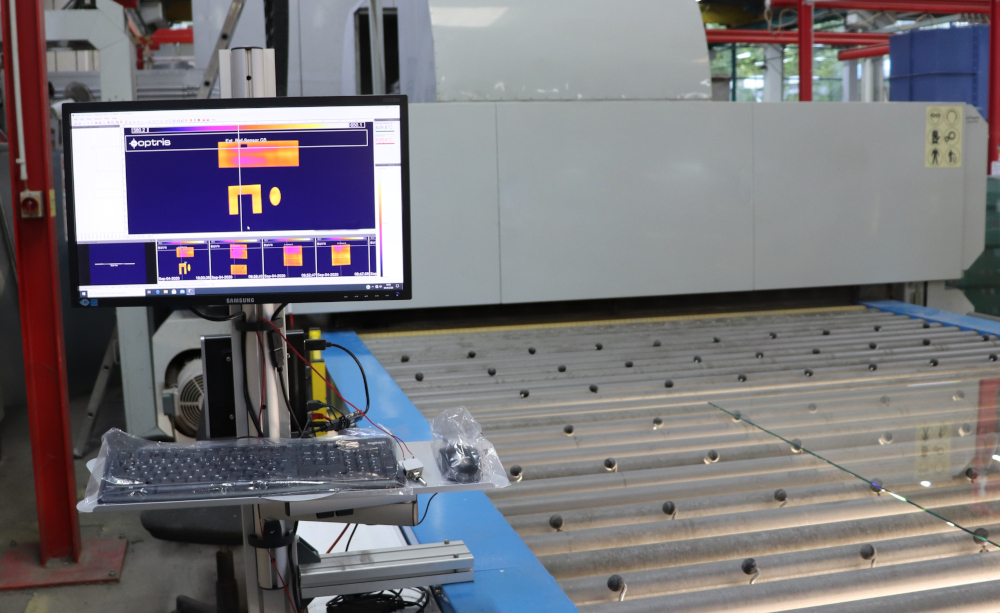

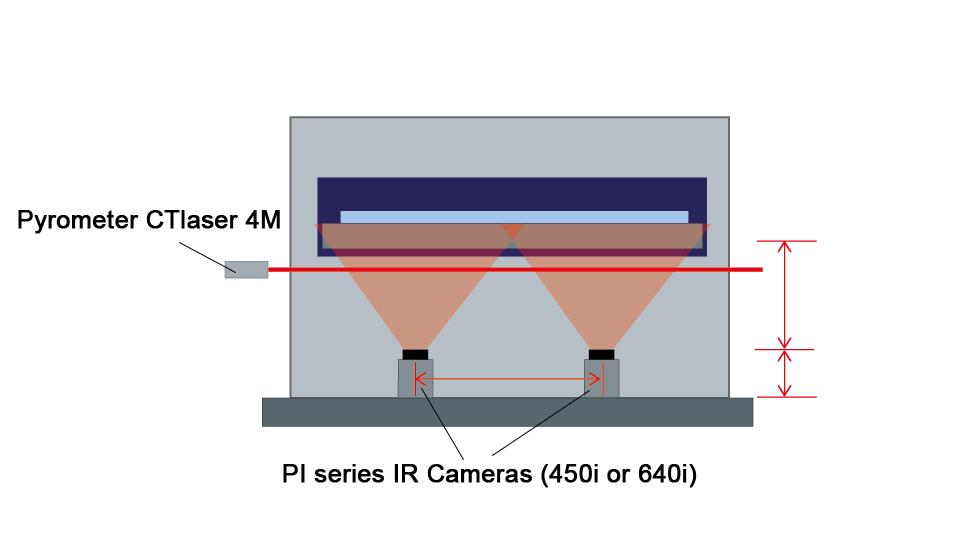

The Bottom Up Glass Inspection System (BUGIS) is an advanced solution designed to monitor and measure the temperature of glass sheets during the tempering process. This system addresses the challenges posed by Low-E glass coatings through a unique bottom-up approach. By utilizing two infrared imagers installed underneath the tempering line, the BUGIS system ensures accurate temperature measurement on the non-coated high emissivity side of the glass. This configuration allows for reliable and reproducible temperature readings, overcoming emissivity variations that depend on the viewing angle of coated glass surfaces.

Optris has developed this optimal solution to ensure precise temperature adherence, which is crucial for the quality of the end product. This involves the absolute temperature value and achieving the most homogeneous temperature distribution possible across the entire glass surface.

Unlike conventional measurement approaches, the BUGIS system’s primary reason is its ability to provide precise temperature measurements. Accurate monitoring is crucial for maintaining the quality of glass products by ensuring uniform heating and cooling during the tempering process. The system contributes to energy-efficient production, particularly important for Low-E glass used in energy-efficient buildings. The BUGIS system’s compact and pre-assembled design facilitates easy installation, even as a retrofit on existing glass tempering furnaces, thus reducing setup time and cost.

The BUGIS system’s measurement approach involves using two VGA infrared imagers, such as the Optris PI 640i G7 or PI 450i G7, which have a spectral response of 7.9 µm optimal for glass temperature measurement. These infrared imagers provide a high-resolution scan line of up to 1600 pixels over a maximum scan width of 4.3 meters, with a maximum viewing angle of 111. The system captures the temperature distribution across the glass surface and calculates the glass surface area. The infrared cameras are connected via a USB interface to a PC running the PIX Connect analysis software, which Optris supplies.

The PIX Connect software analyzes thermographic images in real time and offers comprehensive recording and evaluation options. A computer, installed directly next to the furnace, provides a convenient option for quality assurance with integrated visualization. Additionally, the BUGIS can communicate with the furnace’s PLC, giving employees a direct view of the temperature distribution and other critical information about the glass as it exits the furnace. The false color display allows for a quick assessment of the temperature distribution. If it is less than required, the heating regime in the furnace can be adjusted immediately.

The BUGIS system features high-resolution imaging that ensures detailed temperature mapping, essential for maintaining the quality of glass during the tempering process. It integrates ultra-fast pyrometers with exposure times as short as 90 microseconds and a digitally controlled lens protection system to safeguard against glass breakage.

Innovative Solutions for Low-E Glass Inspection: Optris’ BUGIS System

Low-E glass poses a significant challenge for infrared measurement technology. Used in multi-pane insulating windows, Low-E glass has a coated side with very low emissivity, reducing heat radiation in winter and minimizing room heating from solar radiation in summer.

The Bottom-Up Glass Inspection System (BUGIS) from Optris addresses this challenge and plays a crucial role in the quality control of Low-E glass. By employing two infrared cameras mounted below the toughening line, the system consistently measures temperature on the non-coated, high-emissivity side of the glass.

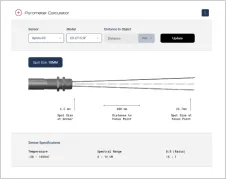

Enhancing the BUGIS system’s efficiency is the ultra-fast Optris CTlaser 4M pyrometer, with a response time of just 90 μs, also mounted underneath. Together with the digitally controlled lens protection system (DCLP), both infrared cameras are reliably protected against glass breakage. The DCLP uses an actuator to move a metal cover in front of the pyrometer or infrared camera when measurements are not being taken. This significantly extends the maintenance intervals for cleaning the optics and eliminates the need for additional compressed air cleaning.

Optris offers the Bottom-Up Glass Inspection System in two versions: the high-resolution GIS 640i G7 and the high-performance GIS 450i G7. Both systems are pre-assembled for easy installation on glass tempering lines. The scope of delivery includes infrared cameras, pyrometers, shutter systems, a compact control cabinet with all electronic and control components, and all necessary cables, providing a comprehensive solution for precise and efficient temperature measurement in glass production.

Recommended Products

Other Glass Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.