Monitoring Jar Filling Efficiency with Infrared Temperature Monitoring

Implementing Infrared Temperature Measurement in Food Production Lines for Efficient Jar Filling

Enhancing Jar Filling Efficiency with Infrared Pyrometer Temperature Monitoring

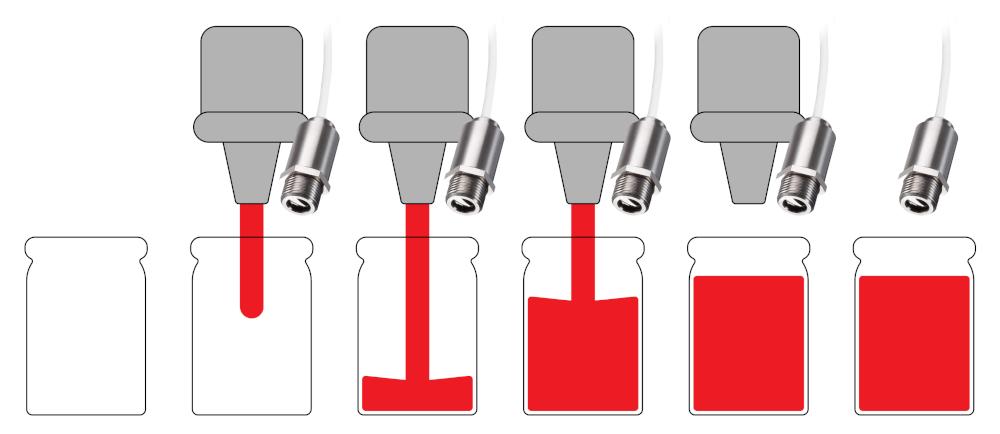

Maintaining the correct temperature during the jar-filling process is crucial in the food industry to ensure the quality and safety of the final product. Jars filled with liquid food must be kept at an optimal temperature neither too hot nor too cold to preserve product integrity. Prior to filling, particularly when using glass jars, thorough cleaning and sterilization are essential. The jars are cleaned with hot water to remove debris, bacteria, yeasts, and fungi that could compromise food safety. During the filling process, these glass jars move rapidly along a conveyor belt at speeds of approximately up to 750 jars per minute, making precise temperature control a challenging task.

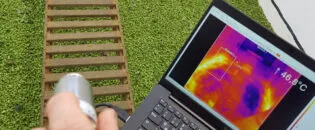

To overcome these challenges, the food processor has adopted a monitoring solution. This system not only measures the temperature of each jar but also counts them as they pass through the production line. Its primary benefit is its ability to detect any temperature deviation, enabling immediate adjustments in production speed to maintain optimal conditions. Moreover, the sensor provides valuable data on the quantity of filled jars, enhancing overall process efficiency and quality assurance.

Leveraging the Cavity Method and High-Speed Pyrometer in Fast Paced Food Production

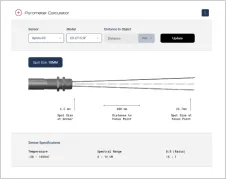

The CT 4M pyrometer is strategically positioned to measure the jars’ temperature by pointing into the opening of each jar, taking advantage of the cavity effect. The cavity method is particularly effective for this application as it ensures the selection of the correct emissivity configuration. When the pyrometer measures the temperature within the cavity formed by the jar’s opening, the multiple reflections of infrared radiation within this cavity increase the apparent emissivity, making it very stable and close to one. This method, often referred to as the wedge method, allows for much more precise temperature measurements compared to flat or exposed surfaces. The use of the cavity method in this scenario is crucial, as it enhances the accuracy of the temperature readings, allowing for real-time monitoring and immediate response if a jar’s temperature exceeds the preset threshold.

The application leverages the ability of the infrared pyrometer to provide accurate temperature readings despite the high speed of the jars. The use of the CT 4M pyrometer in this scenario is crucial, as it allows for real-time monitoring and immediate response if a jar’s temperature exceeds the preset threshold. The system is designed to trigger alarms and control mechanisms to adjust the temperature, ensuring each jar meets the required conditions. The CT 4M pyrometer’s ability to detect temperature variations quickly and accurately is enhanced by the use of a parameter sensor installed alongside the pyrometer. This sensor verifies the presence of each jar, ensuring that every container is accounted for during the temperature monitoring process. The system outputs signals via a 4 to 20 mA signal into the PLC, enabling precise counting of jars and monitoring of their temperatures. This setup not only guarantees that the jars are filled at the correct temperature but also provides data that can be used to improve the efficiency of the production process. The infrared pyrometer and sensors work together seamlessly, offering a reliable and cost-effective solution for the challenges faced in high-speed food production environments.

Reliable Temperature Control in High-Speed Production with Optris’ CT 4M Pyrometer

The implementation of Optris’ infrared temperature monitoring solution has resulted in significant benefits for the customer. By ensuring that each jar is filled at the optimal temperature, the customer has been able to maintain high product quality. The precise measurement capabilities of the CT 4M pyrometer, combined with the reliable presence detection from the parameter sensor, have provided the customer with a robust solution that addresses the challenges of high-speed production.

One of the key advantages of working with Optris is the exceptional technical support provided throughout the implementation process. The system’s ease of setup allowed the customer, who had limited technical expertise, to quickly integrate the solution into their production line with minimal disruption. Optris’ close collaboration with the customer and their distributor ensured that the infrared pyrometer functioned correctly in the field, delivering reliable performance. The cost-effectiveness of the solution, coupled with its high accuracy and reliability, made it a clear choice for the customer. These factors, along with Optris’ commitment to customer satisfaction, highlight why Optris is the preferred partner for infrared temperature measurement solutions in the food industry.

Recommended Products

Other Food Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.