Optimizing Tire Curing and Vulcanizing Processes with Infrared Technology

Challenges of Ambient Temperature Variations in Tire Manufacturing

The Role of Temperature, Pressure, and Time in Tire Vulcanization

A “green tire” is a tire that has been assembled with all its components but has not yet undergone curing or had the treads added. Also known as an “uncured” tire, it remains raw and unvulcanized. Tire production begins with the preparation of a mixture of rubber, oil, and additives, which is then processed through various machines to form the individual components of the tire, such as the inner rubber liner, plies, belts, bead, sidewall, and tread. These parts are assembled on a tire-building machine and pressed into the familiar tire shape.

The final stage in tire production is vulcanization, where the tire is subjected to specific temperatures and pressures, causing the rubber to undergo chemical reactions. This process transforms the linear rubber molecules into a three-dimensional network, giving the material its valuable physical and mechanical properties. Temperature, pressure, and time are critical factors in vulcanization, often referred to as the “three elements of vulcanization.” Their precise control is essential for producing high-quality tires.

Once a tire reaches the green stage, it is placed in a mold for curing. The green tire will then be placed in a mold and taken to be cured. A green tire is placed inside a large mold for the curing process, which consists of the tire being inflated and heated to get the proper shape and tread. During the curing process, the green tire is heated up to ~200 °C (392 °F) to bond each element. The curing process depends on the size of the tire and can take anywhere from 15 minutes to an entire day.

In tire manufacturing, the curing process is critical for ensuring the durability and quality of the final product. This process involves heating the green tire to a precise temperature, allowing the rubber to vulcanize and achieve the desired properties. However, variations in ambient temperature, especially those due to seasonal changes, pose significant challenges. For instance, the green tire’s temperature, when placed on the curing press, can vary depending on the conditions in the storage area or the curing area itself. This inconsistency can lead to undercooking or overcooking, which in turn can result in tires with compromised durability or performance, posing a risk to the end users.

The desire to maintain consistent quality drives the need for precise temperature measurement in the tire curing process. Traditional methods of managing the curing time, based solely on a preset duration, need to be revised as they do not consider variations in the initial temperature of the green tire. The introduction of infrared temperature measurement allows for an accurate assessment of the temperature of each tire before curing, enabling dynamic adjustments to the curing time and ensuring each tire undergoes the optimal process regardless of external conditions.

Implementing Non-Contact Temperature Measurement in Tire Manufacturing

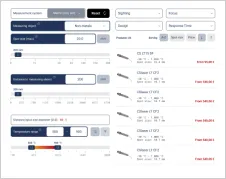

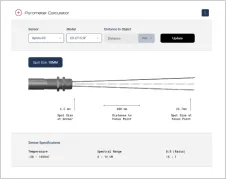

Optris offers industrial infrared temperature measurement sensors to address the challenges in the tire curing process. In this application, OEM manufacturers in Asia utilize Optris CTlaser LT. These infrared sensors monitor the temperature of the green tire before the curing process.

Green tires are stored before the curing process, and the ambient temperature of the storage area varies with the seasons and the day/night cycle. Additionally, green tires are kept near the curing area, where they are also subject to changes in ambient temperature. Each tire type has a predetermined curing time, which remains fixed regardless of the green tire’s temperature when loaded into the curing process. The pyrometers can measure the tire’s surface temperature significantly, so a high distance-to-spot size ratio is required.

The high rubber emissivity is highly compatible with Optris measurement devices, particularly those operating within the LT spectral band. Rubber’s natural high emissivity allows for accurate and reliable temperature readings, ensuring that the Optris devices can effectively monitor and control processes like tire curing. This compatibility enhances the precision of measurements, making Optris devices ideal for applications where consistent and accurate temperature monitoring of rubber is critical. Optris’s infrared technology is particularly well-suited for this application due to its precision and adaptability. The infrared sensors can operate effectively in varying environmental conditions, ensuring accurate measurements even when the ambient temperature fluctuates. Additionally, the system is designed to integrate seamlessly with existing curing processes, minimizing the need for extensive modifications to the production line. By using this infrared solution, tire manufacturers can optimize the curing process for each tire, improving overall product quality and reducing the risk of defects.

The temperature data collected by the infrared sensors is then fed via 4-20mA signal into a programmable logic controller (PLC), which adjusts the curing time based on the measured temperature. Based on the green tire temperature, an algorithm on the PLC adjusts the optimum cure time to eliminate tire scrap due to overcooking. Tire scraps due to undercooking will be eliminated. The red laser sighting on the black rubber surface is convenient for adjustments and alignment.

Significant Improvements in Tire Output, Consistency in Tire Quality and Energy Efficiency

The implementation of Optris’s infrared temperature measurement solution has led to significant improvements in tire curing processes. By accurately measuring the temperature of each green tire, manufacturers can ensure that the curing time is perfectly matched to the tire’s initial conditions. This optimization has resulted in a 4% increase in tire output and a similar percentage of energy savings, demonstrating the system’s efficiency and effectiveness.

Furthermore, the use of infrared sensors eliminates the variability that can occur due to changes in ambient temperature, resulting in more consistent tire quality. This consistency reduces waste and lowers production costs, as fewer tires are rejected due to defects. Optris stands out as a preferred partner for tire manufacturers due to its expertise in infrared technology and its commitment to providing solutions that enhance quality and efficiency. The precision, reliability, and ease of integration of Optris’s infrared sensors make them the ideal choice for optimizing tire curing processes.

Recommended Products

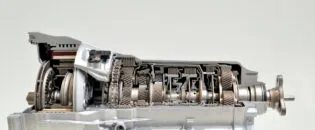

Other Automotive Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.