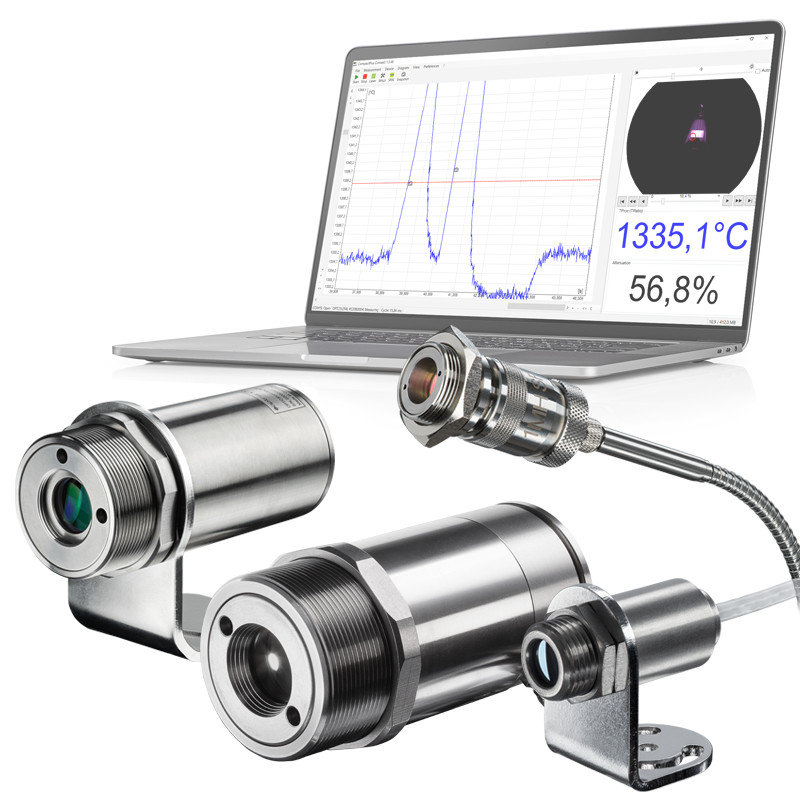

CompactPlus Connect for High-end Infrared Pyrometers

Extensive License-free Software for High-end Infrared Pyrometers

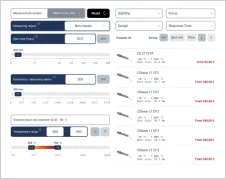

Software Highlights of the CompactPlus Connect

- No additional cost and no limitation in licensing

- Temperature over Time Data Recording

- Advanced signal processing

- Complete parametrization of sensors via software

- Automatic process control

- Temperature data analysis and documentation

- Customer-specific software adjustments

- Digital and graphical displays

- Multiple software instances

Download of the Latest CompactPlus Connect Software

DOWNLOAD

ZIP – 102.93 MB

CompactPlus Connect 1.6.45 2024-08-A

Complete the form to download the file

Software Archive

DOWNLOAD

ZIP – 79.7 MB

CompactPlus Connect 1.6.29 2024-02-A

Complete the form to download the file

DOWNLOAD

ZIP – 47.21 MB

CompactPlus Connect 1.6.17 2023-10-A

Complete the form to download the file

Full Support for Optris Pyrometers, No Extra Cost

The CompactPlus Connect software, developed by Optris, is a robust and versatile free tool designed to enhance the functionality of high-end infrared thermometers. This software provides extensive features for temperature data analysis, ensuring precise and reliable measurement results. Key functionalities include automatic process control, which facilitates seamless integration into various industrial processes, and comprehensive device parameterization, allowing users to tailor the pyrometer to their specific application needs.

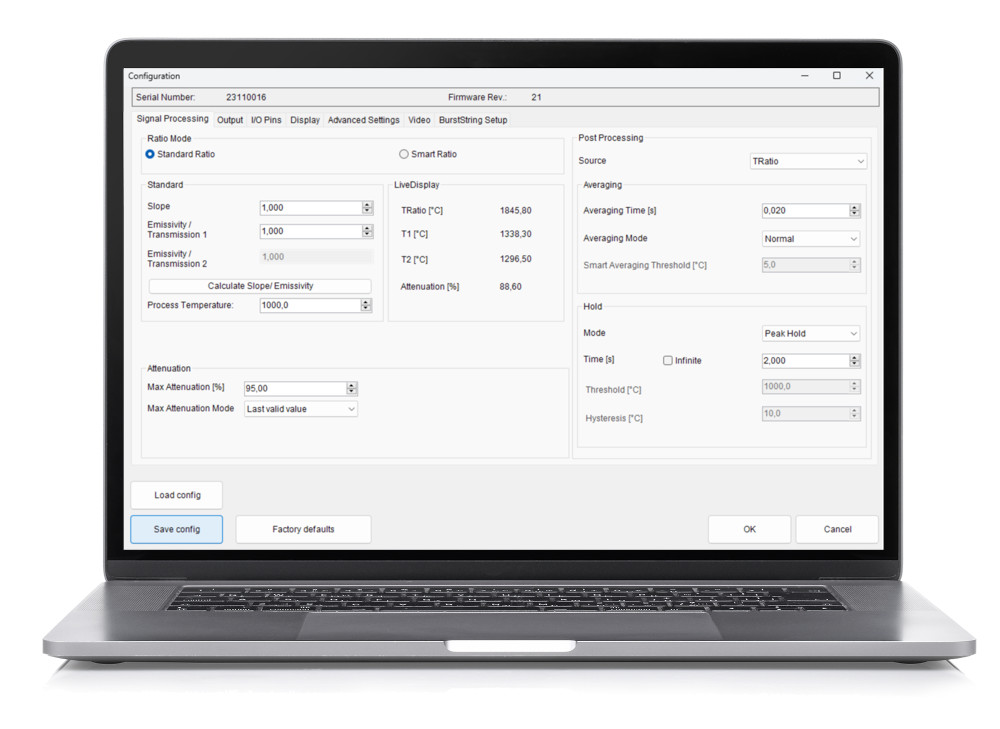

One of the standout features of CompactPlus Connect is its capability for manual, one-point, and two-point adjustments. These calibration methods empower users to fine-tune temperature measurements, ensuring high accuracy across different applications. The software’s robust support for digital field communication further enhances its adaptability, giving users the power to manage multiple sensors within a single network. This is particularly beneficial for complex setups that require synchronized data collection from various points, allowing for tailored application needs.

Moreover, CompactPlus Connect includes advanced signal processing features such as smart averaging, which helps smooth out signal fluctuations, providing more stable and reliable temperature readings. Users can also benefit from extensive logging and display options. The software can visualize temperature data in real-time, offering various views and external display capabilities to suit different monitoring needs.

The user interface of CompactPlus Connect is thoughtfully designed for ease of use, featuring customizable screens and digital displays. It supports multiple languages, ensuring accessibility for a global user base. Additionally, the software can be configured to automatically start measurements, enhancing the efficiency of routine operations. This emphasis on user-friendliness and inclusivity is a testament to Optris’ commitment to user comfort and convenience, making the experience with the software as smooth as possible.

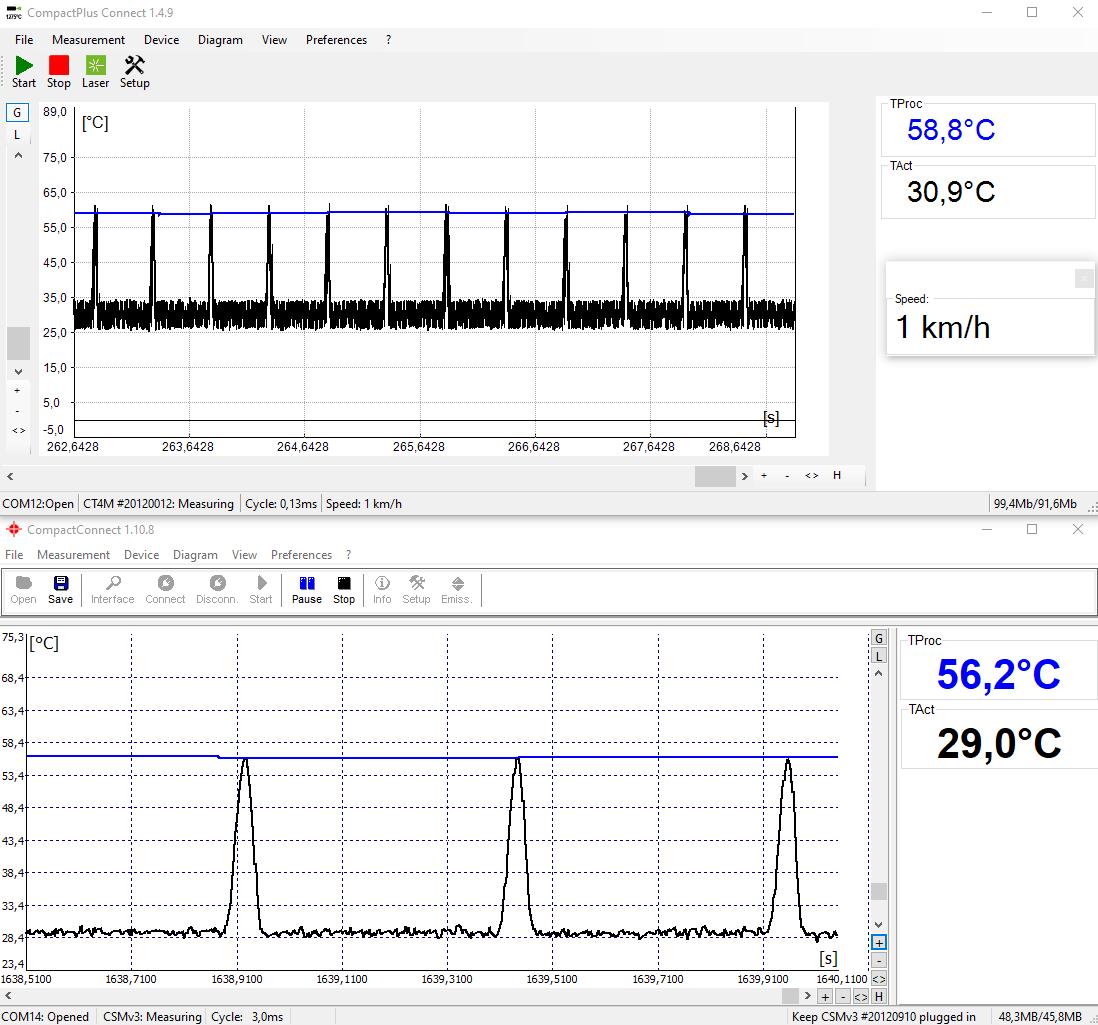

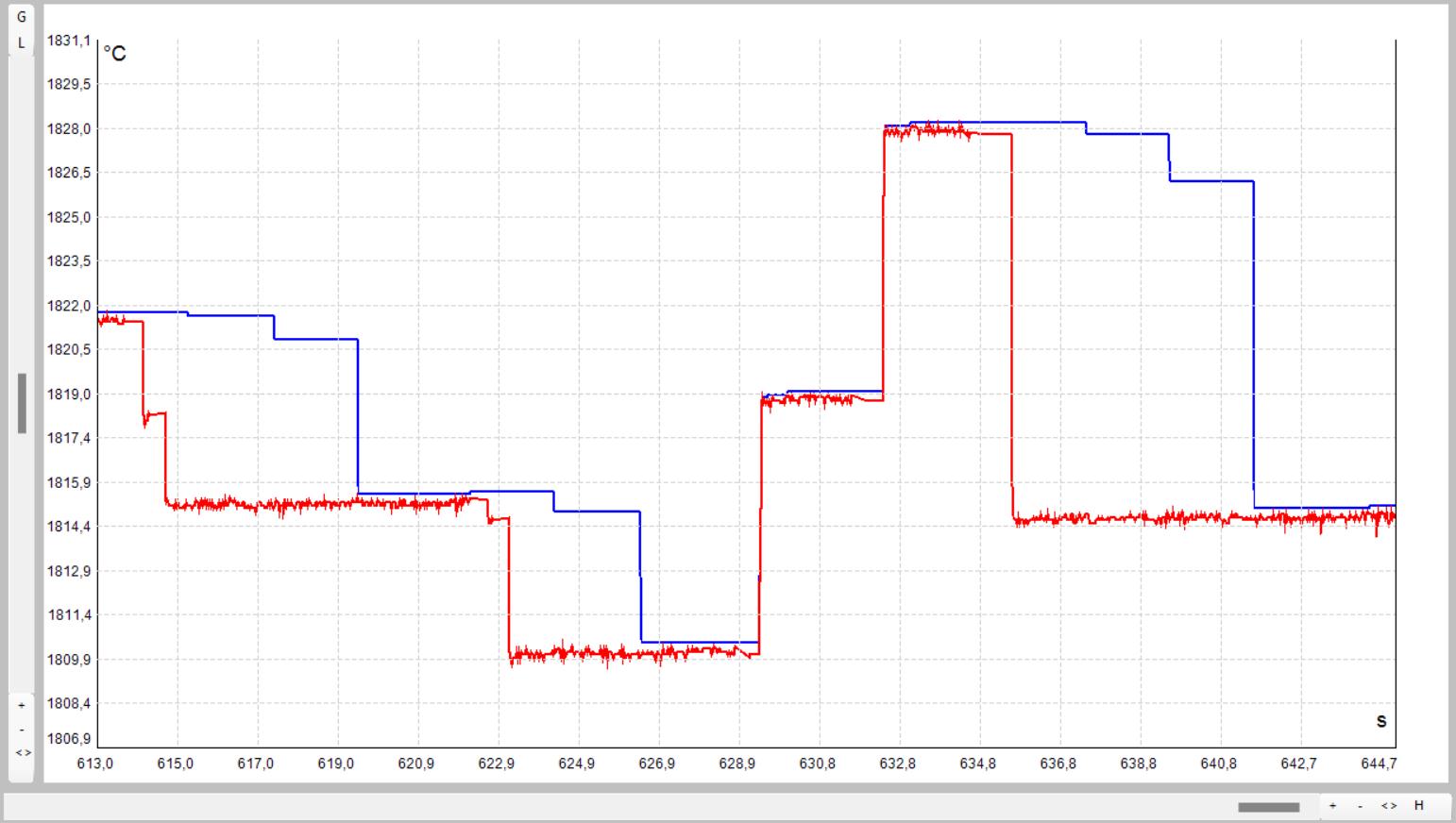

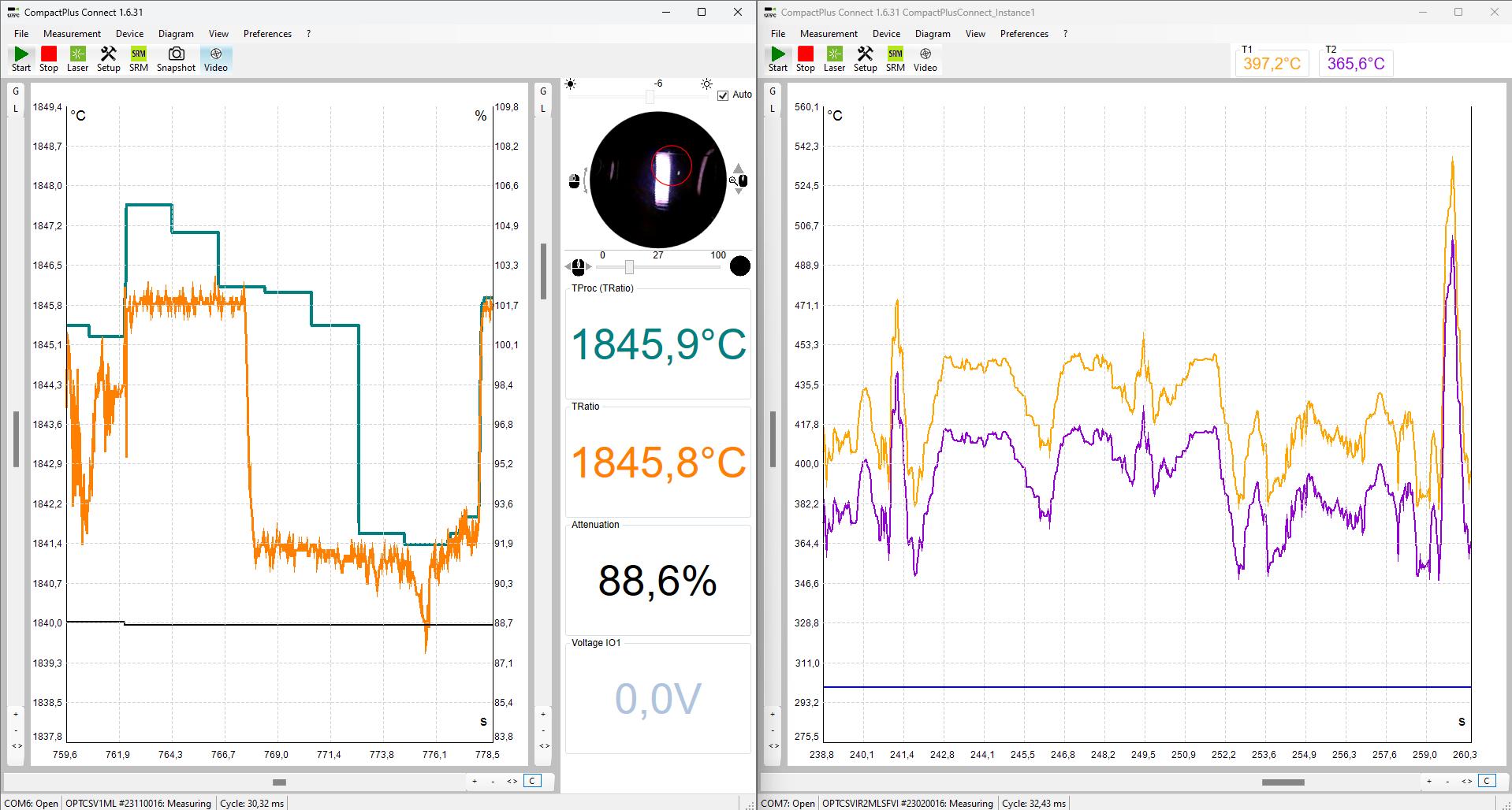

Visualization of Temperature Trends

The CompactPlus Connect software displays temperature values in real-time through temperature-time diagrams and digital displays, providing up-to-the-second information on ratio, minimum, and maximum values. Users can select automatic or manual scale adjustments for optimal visualization, ensuring accurate and clear representation of temperature readings.

The software also supports data recording for detailed analysis and documentation, with triggered data collection to capture specific events and measurements precisely. This feature enables users to conduct thorough analyses and maintain comprehensive records, facilitating precise monitoring and assessment of temperature data in various applications.

Advanced Signal Processing Capabilities and Programmable Inputs and Outputs

The CompactPlus Connect software offers advanced signal processing capabilities, including smart averaging, peak hold, and valley hold functions. These features smooth out fluctuations, capture significant peaks and valleys, and ensure accurate temperature readings. Users can customize averaging times and thresholds to match their specific requirements.

These processed signals can be scaled and forwarded to the pyrometers functional outputs and inputs for integration into a closed control loop. This flexibility in signal processing and customization allows for seamless integration into various industrial processes, ensuring precise and reliable temperature control and monitoring.

Customer Specific Software Adjustments

The CompactPlus Connect software offers various language options and a translation tool, displaying temperatures in °C or °F, and allows layout adjustments for user convenience. Users can load and save measurement parameter settings tailored for specific applications, enhancing efficiency and consistency.

Additionally, the software enables the starting of different stages to display multiple sensors simultaneously, increasing flexibility and usability in diverse environments. This feature is particularly beneficial for complex setups, allowing users to monitor and manage multiple data points concurrently, ensuring comprehensive temperature analysis and control.

Saving and Restoring Configuration and Parametrization of the Infrared Sensors

The CompactPlus Connect software allows users to save and restore configuration settings, including the pyrometers parameterization. This feature enables quick setup by loading predefined settings tailored to specific applications.

Users can save current sensor configurations into files and restore them when needed, ensuring a quick recovery if the pyrometers settings have been altered.

This functionality simplifies managing multiple setups and reduces downtime in production, making it an invaluable tool for maintaining efficiency and consistency across various industrial processes.

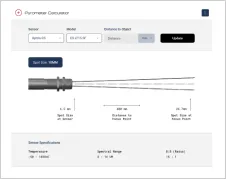

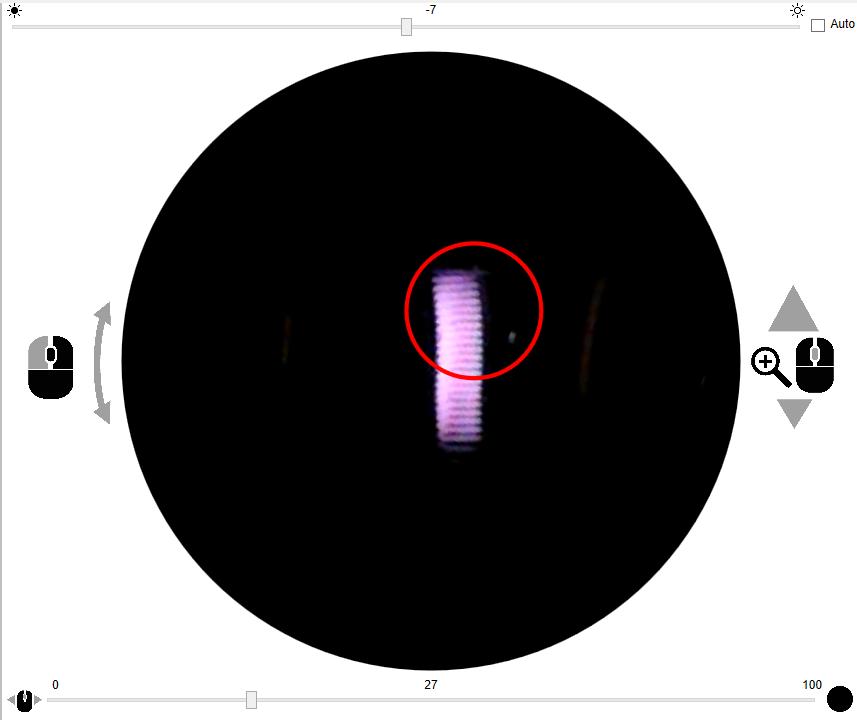

Live Video Feed and Laser Control for Pyrometer Alignment

For video pyrometers, the CompactPlus Connect software includes video signal capabilities for precise alignment of the measuring spot. Users can control the brightness filter, and rotate and zoom the video screen for optimal viewing. Additionally, snapshots can be triggered if an alarm value is reached, providing visual documentation related to the measurement.

The software also allows convenient control of the pyrometers laser, which is used for alignment. These features enhance the accuracy and ease of use of video pyrometers, making it simpler to monitor and adjust measurements in various applications.

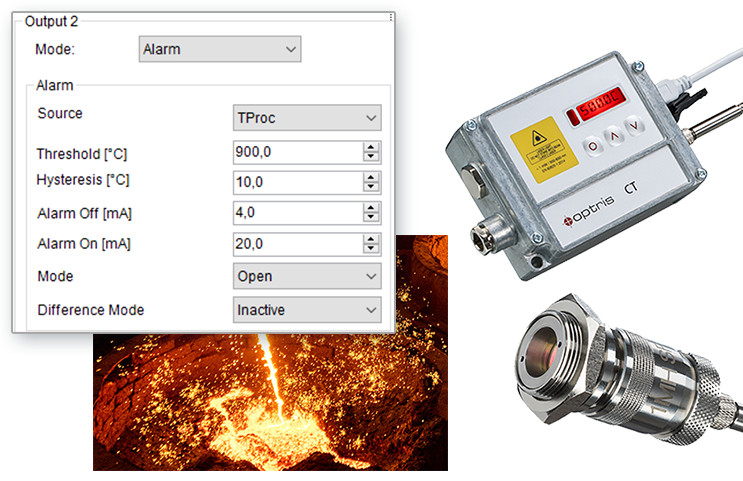

Setup of Alarms and Warning Thresholds

The CompactPlus Connect software allows users to set up alarms for temperature monitoring, which can be configured based on specific thresholds. This ensures immediate notification if temperature values exceed or fall below the defined limits. The alarm can be forwarded to the digital outputs of the pyrometer, enabling integration into broader control systems.

This alarm feature enhances safety and process control by enabling prompt responses to critical temperature changes, ensuring optimal operation and preventing potential issues.

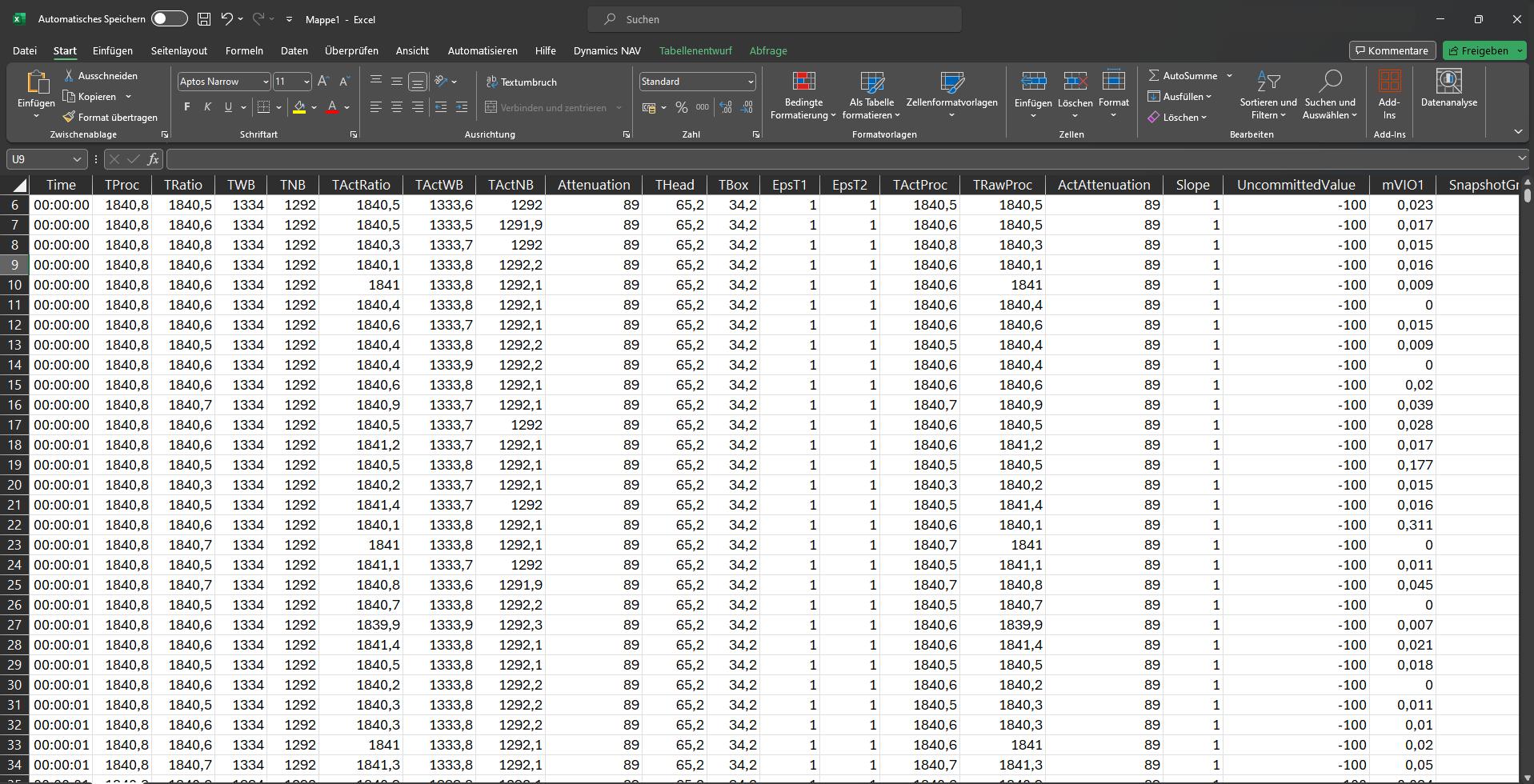

Export of Temperature Measurement Data

The CompactPlus Connect software allows detailed post-processing analysis of temperature-time diagrams. Temperature data can be saved in Excel files for further processing, ensuring easy integration with other data analysis workflows such as Python or Matlab. Additionally, the diagram window can be saved to the clipboard, making it convenient to use in standard programs such as MS Word for reporting and documentation purposes.

This functionality streamlines the process of analyzing and sharing temperature data, facilitating comprehensive assessments and efficient communication of results.

Digital Communication and Documentation for own Software Solutions

The CompactPlus Connect software includes robust digital communication capabilities, complete documentation, and a binary chat program. This example program allows users to test and verify communication with connected infrared sensors, facilitating the integration of Optris online thermometers into their own software solutions.

Users can troubleshoot, test, and optimize sensor performance by sending binary commands and receiving responses. This feature enhances the software’s adaptability and ensures that users can maintain optimal sensor performance while seamlessly integrating Optris technology into their existing systems.

Continuously Maintained and Supported

The CompactPlus Connect software is continuously maintained and supported by Optris. Regular updates ensure that the software stays current with the latest technological advancements, enhancing performance and reliability.

This commitment to ongoing support and improvement ensures that users benefit from the most up-to-date features and capabilities, maintaining optimal functionality and efficiency in their temperature measurement processes.

Standalone Software without Internet connection required

The CompactPlus Connect software operates autonomously and standalone without requiring an internet connection, making it ideal for cybersecurity-critical applications. All data is processed on the pyrometer, with the software used solely for visualization of the temperature data and configuration of the pyrometer.

This design ensures that sensitive information remains secure, providing a reliable solution for environments where cybersecurity is a top priority.

Firmware Updates

The CompactPlus Connect software is essential for performing firmware updates on Optris devices. This functionality ensures that all devices remain up-to-date with the latest features and improvements.

Users can easily update firmware, enhancing device performance and ensuring compatibility with new software developments. Regular updates help maintain the optimal operation of the devices, ensuring they continue to perform reliably and efficiently in various applications.

Hardware Requirements

Minimum system requirements:

- Windows operating system

- USB 2.0-interface

- At least 128 MB RAM

- Hard disc with at least 30 MByte freespace

- 2,0 GHz processor power

Recommended system requirements:

- Windows 10

- At least 2 GB hard disk storage for measurements

- At least 2 GB RAM

Documentation

Download

DOWNLOAD

TXT – 2.9 KB

CompactPlus Connect Changelog

Complete the form to download the file

FAQs

What is the difference between the CompactPlus Connect and the CompactConnect?

The main difference between CompactPlus Connect and CompactConnect is their support for different generations of infrared sensors. CompactPlus Connect is the successor to CompactConnect and supports the most novel infrared sensors, incorporating the latest advancements and features. In contrast, CompactConnect is designed to support legacy products, ensuring continued functionality and support for older devices. This distinction allows users to choose the software version that best meets their needs based on the specific infrared sensors they are using.

Where is the temperature data signal processed?

The temperature data signal is processed within the pyrometer itself. Our software plays a crucial role in configuring the pyrometer and providing a visual representation of the measurement data. The pyrometer is responsible for storing the configuration and processing the measurement data signal, ensuring accurate and efficient temperature monitoring and control.

How can I restore the configuration of a pyrometer?

To restore the configuration of a pyrometer, the best practice is to store a copy of the pyrometers configuration on your computer. If needed, you can then load this saved configuration back into the pyrometer. This approach ensures that you can quickly and easily restore the pyrometers settings, maintaining consistency and reducing downtime in your processes.

Does the software run on Linux?

No, unfortunately, the software is a native Windows program and does not run on Linux.