Calibration Service

Ensuring Precision and Accuracy for all Optris Devices

Regularly checking your pyrometers or thermal imagers is essential to preventing measurement errors and ensuring accurate results. Our comprehensive calibration and adjustment process reflects our commitment to precision.

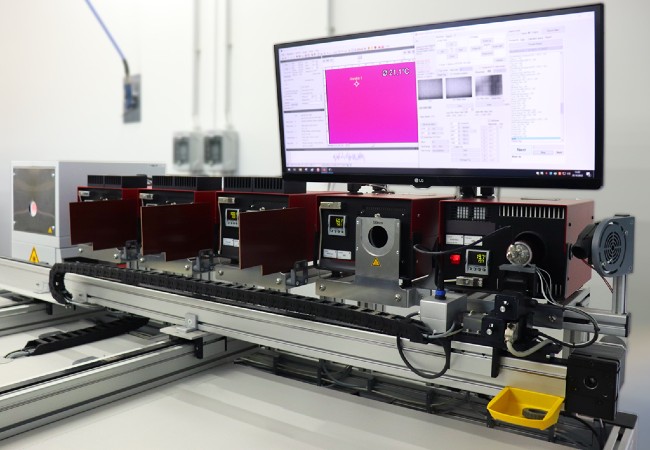

This process is carried out in our state-of-the-art in-house calibration laboratories, where every parameter, including laboratory temperature, humidity, measurement distance, and source diameter (calibration geometry), is meticulously documented. You can trust the reliability of our services.

At Optris, our reference devices undergo annual inspection by the National Metrology Institute of Germany (Physikalisch-Technische Bundesanstalt, PTB), ensuring that our temperature measurement instruments meet the high standards required for quality control processes.

Additionally, the NIST (National Institute of Standards and Technology) standard can be applied to our infrared instruments. NIST establishes the guidelines for the consistent and accurate measurement of temperature using infrared technology.

As a U.S. federal agency, NIST ensures the quality and precision of measurement tools across various industries, including metal processing, aerospace, and electronics manufacturing. Its standards ensure reliable and traceable temperature readings, in alignment with international metrology systems, ensuring global consistency in thermal measurements and calibration practices.

Customer Support

Expert Guidance and Support Worldwide

Optris offers personalized support for repairs and calibration services through experienced engineers. We ensure competent, reliable service, collaborating with numerous global distribution partners to meet your needs effectively.

Contact UsHow does it work?

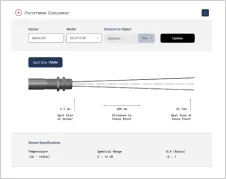

Infrared temperature measuring devices are calibrated with the aid of black bodies, radiation sources that can produce different temperatures with exceptional stability. For a precise calibration process, it is crucial to know the exact value of the radiation temperature. This value is typically measured using a contact thermometer or a transfer standard radiation thermometer and is then used to adjust or calibrate the infrared sensors.

Whether performed by the customer or an accredited calibration laboratory, the calibration temperatures should correspond to those found in the relevant application to ensure accuracy. Transfer standard radiation thermometers, which are calibrated at the Physikalisch-Technische Bundesanstalt (PTB), are used to measure the radiation temperature of the reference sources. Based on PTB-certified pyrometers, we manufacture infrared temperature measurement devices with traceable calibration according to the ITS-90 standard.

In addition to PTB certification, infrared devices can also be calibrated following the NIST standard. The National Institute of Standards and Technology (NIST) provides a recognized framework for the calibration of infrared pyrometers and ensures measurement accuracy across industries. NIST-certified infrared temperature sensors are calibrated against rigorous guidelines for measurement uncertainty and reference temperatures. These standards support precise and reliable temperature readings in industries like metal processing, aerospace, and electronics manufacturing. With NIST standards grounded in international metrology systems, infrared temperature devices receive a globally consistent and reliable calibration, further reinforcing the accuracy and traceability essential for high-stakes industrial applications.

At what temperatures are the sensors calibrated?

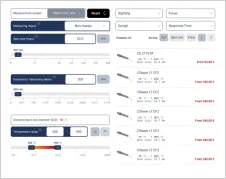

Calibration temperatures can be selected within a wide range, from -20°C to 3000°C, depending on your specific needs. For sensors purchased from stock for quick shipment, a standard calibration temperature set is used. For more details or to request a customized calibration temperature range, please contact our application engineers.

How to obtain a calibration certificate?

For each infrared measurement device we supply a calibration certificate for low cost.

The calibration certificate will be included in the purchase shipment, documenting the measuring accuracy of the IR sensor or thermal imager by using three different measurement values within the temperature measurement range.

The calibration certificates of our own reference devices can be obtained by contacting our Sales and Service teams.

How often should my infrared measuring devices be calibrated?

To ensure reliable temperature measurement results, Optris recommends the annual inspection of your devices in line with our calibration service. Infrared thermometers and thermal imagers will be checked for malfunctions by documenting not only the room temperature and humidity of the calibration laboratory, but also the measuring distance as well as the radiation diameter (calibration geometry).

Precise measuring devices are key in process monitoring procedures. You are welcome to learn more about our included services, ensuring the accurate functioning of your devices.

What is Optris’ expertise in standardization?

Not only are high technical standards applied to the production of measuring devices, but also in the active participation in sector wide standardization processes. At the moment development engineers are working, among other areas, in the working groups for Applied Radiation Thermometry (GMA 8.1) and Temperature Measurement with Thermal Imaging Cameras (GMA 8.16) of the Verein Deutscher Ingenieure (VDI).