Infrared Food Temperature Control for Commercial Frozen Meat Shredding

The Importance of Noncontact Temperature Monitoring in Frozen Meat Processing

Protecting Equipment and Ensuring Meat Safety with Accurate Temperature Control

Recognizing the critical role of temperature in frozen meat processing, a food processor specifically requests precise noncontact temperature monitoring of frozen meat blocks. Their goal is to protect their shredding machines from damage and safeguard the meat from microbiological hazards. This proactive step demonstrates their deep understanding of the importance of this aspect in their operations and their commitment to maintaining high standards of quality and safety.

Accurate sensing technologies for temperature control are crucial in the industrial processing of frozen meat. This meat food process begins with delivering and storing raw frozen meat, kept at around -18°C or colder temperatures. Maintaining this temperature is essential to preserve the meat’s microbiological safety and ensure uniform consistency during further processing.

A critical stage in this process is shredding frozen meat blocks, where the meat is introduced into a shredder or similar machinery. If the meat is too cold, significantly below -18°C, it becomes extremely hard and brittle, leading to challenges in cutting, increased wear on cutting tools, and higher maintenance costs. Furthermore, the quality of the shredded product can be compromised, as the meat may fracture or splinter instead of cutting cleanly. On the other hand, if the meat is too warm, just below 0°C, it loses its firmness and may smear or stick during shredding, causing blockages and uneven cutting, negatively impacting the end product’s quality.

Moreover, if the cooling during the shredding process is inadequate, the meat’s temperature can rise uncontrollably, posing a significant microbiological risk. Higher temperatures foster bacterial growth, potentially compromising the safety of processed meat. In light of these potential hazards, accurate temperature monitoring is beneficial and crucial for protecting equipment and ensuring the quality and safety of the processed meat.

The ideal temperature range for shredding meat is between -12°C and -15°C. Within this range, the meat remains frozen but is not excessively hard, allowing for efficient shredding with minimal stress on the machinery. Accurate monitoring of these temperatures is therefore essential to maintain consistent product quality and prevent damage to processing equipment.

Ensuring Precise Temperature Control in Meat Shredding with Autonomous IR Monitoring

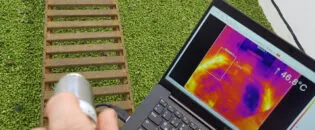

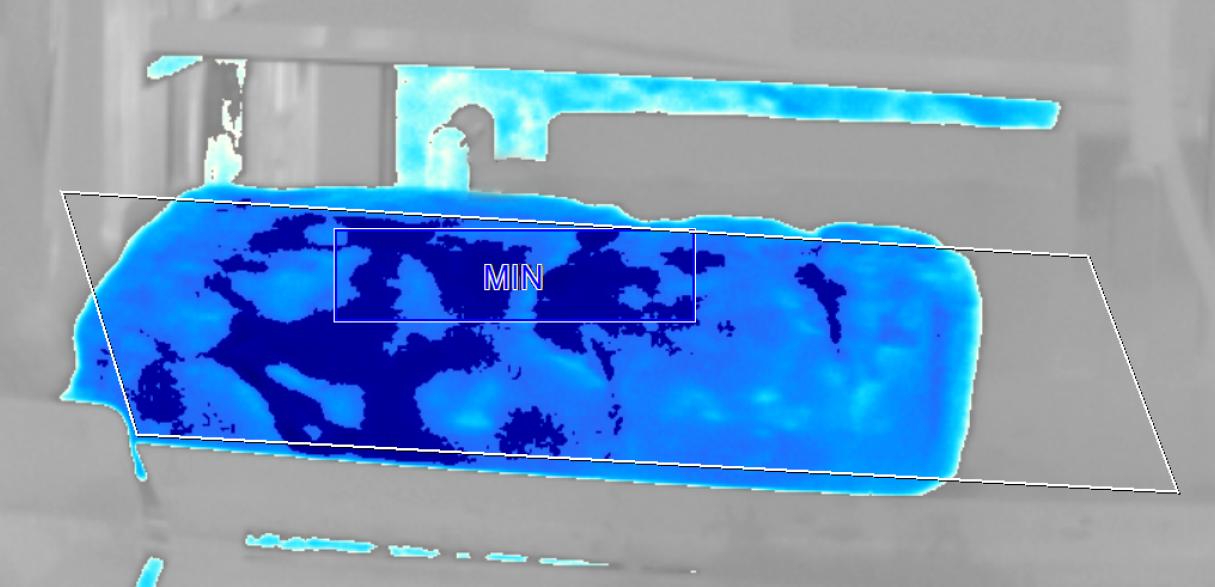

In this application, the Optris Xi 410 infrared camera is mounted next to the shredder, providing a precise and efficient solution for monitoring the temperature of frozen meat blocks during processing. The infrared camera measures the meat’s temperature without physical contact, ensuring accurate readings and uninterrupted workflow. If the temperature falls too low, an alarm is triggered, prompting the system to slow down the process, allowing the meat to warm up gradually. This helps prevent equipment damage and reduces maintenance costs. Conversely, if the meat is too warm, another alarm activates, prompting an adjustment in cooling or an increase in processing speed. This ensures the cold chain is consistently monitored and maintained.

Equipped with a mid-resolution sensor (384 x 240 pixels), the Xi 410 delivers precise temperature measurements over a wide range, from -20°C to 900°C. Its motorized focus and compact design allow seamless integration into various applications, particularly in food processing industries.

A standout feature of the Xi 410 is its ability to operate autonomously. With an auto hot or cold spot finder, the camera can directly output analog signals or trigger alarms when critical temperature thresholds are reached. This is especially valuable in frozen meat processing, where maintaining the ideal shredding temperature between -12°C and -15°C is crucial for efficient processing and equipment protection.

With a thermal sensitivity (NETD) of 60 mK, the Xi 410 detects even the slightest temperature variations in meat blocks, ensuring high accuracy. The accompanying PIX Connect software further enhances its capabilities by offering detailed analysis, allowing operators to customize measurement fields and set specific temperature thresholds to meet processing requirements.

Designed for demanding industrial environments, the Xi 410 is housed in a rugged, IP67-rated enclosure. This enclosure offers protection against dust, moisture, and extreme ambient conditions, making it a reliable choice for harsh production settings.

Prevent Downtime and Preserve Quality with the Autonomous Optris Xi 410

The Optris Xi 410 infrared camera is a precision tool that has revolutionized frozen meat processing for commercial food processors. Its ability to accurately monitor the temperature of meat blocks before and during shredding ensures that the process stays within the optimal temperature range, preventing equipment damage and preserving product quality.

With autonomous operation, the Xi 410 provides up to three analog or alarm outputs, enabling continuous temperature monitoring without requiring constant manual oversight. All frozen meat blocks are automatically measured and evaluated, and alarms are triggered if critical temperatures are detected. This prevents costly downtime and ensures the processing line runs efficiently. The camera also offers flexible connectivity options, including Fast Ethernet, USB 2.0, and RS485, making it highly adaptable and easy to integrate into various control systems.

Additionally, the integration with PIX Connect software enhances its value, offering real-time data analysis and enabling immediate corrective actions. This minimizes production delays and reduces the risk of product spoilage, ensuring a smooth and reliable workflow.

The Xi 410’s versatility is further demonstrated by its multiple field-of-view options and stackable process interfaces, allowing it to adapt to different production setups. With a competitive price-performance ratio, it’s an ideal choice for food producers seeking a cost-effective, reliable, and efficient temperature monitoring solution.

Recommended Products

Other Food Applications

Talk to us about your IR Temperature Measurement Requirements

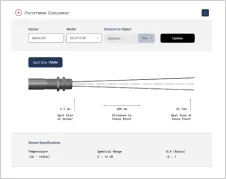

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.