Thermography Optimizes Gritting and De-Icing Efforts on Salt Trucks

Reducing Costs and Environmental Impact with Infrared Temperature Monitoring

Reducing Costs and Environmental Impact through Optimizing Gritting Efforts with Infrared Measurement

Ice formation on roads creates hazardous driving conditions by drastically reducing road surface friction, increasing the risk of accidents.

Traditional methods of detecting and treating road ice, like the widespread application of de-icing chemicals such as sodium chloride, are both expensive and environmentally harmful. These chemicals can contaminate groundwater and damage roadside vegetation. Adjusting the spread of de-icing materials according to current weather and road conditions is crucial. Lower temperatures require more salt to achieve the same de-icing effect. However, manual adjustments often lead to the over-application of salt, which is both wasteful and unnecessary.

Accurate road temperature data is essential for authorities’ road weather information systems to monitor current conditions. By combining temperature measurements with other meteorological data, these systems can produce more accurate forecasts and provide better decision-making support for winter road maintenance. Monitoring road temperatures is vital for predicting ice formation, enabling timely interventions such as the application of de-icing agents or other necessary maintenance actions. When combined with air temperature, relative humidity, and dew point data, non-invasive temperature measurement methods provide an accurate representation of road conditions. Recent interest in non-intrusive methods, such as infrared thermometry, highlights their advantages over traditional surface-mounted sensors, particularly in wet, snowy, or icy conditions.

By using precise road temperature measurements, salt costs and environmental impacts can be minimized. This optimization not only ensures the efficient use of de-icing agents but also reduces waste and environmental damage, thereby providing a cost-effective solution for road maintenance.

Road surface temperatures can vary significantly across locations and at different times, even within short distances along the same road. A road condition monitoring system installed on sprayers, spreaders, and gritter trucks plays a crucial role in reducing waste. By automatically and continuously adjusting the dosage of spreading materials based on road temperature, this system ensures that de-icing agents are used only when and where necessary, thereby conserving resources and reducing environmental impact.

High-Sensitivity Infrared Pyrometers for Real-Time Temperature Road Monitoring on Salt Trucks

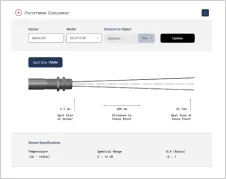

In several applications, the CSlaser hs and CSmicro hs pyrometers have been installed on salt trucks to monitor road surface temperatures effectively. These sensors are mounted externally on the trucks, where their lenses can be susceptible to dirt or scratches, potentially compromising their ability to measure infrared radiation accurately. To address this, the infrared sensor is often housed within a cone-shaped pavement probe that protects it from road spray, significantly improving accuracy by preventing dirt accumulation. This setup ensures continuous and reliable monitoring of road surface temperatures, providing instant feedback on current conditions and enabling real-time responses, thereby enhancing the efficiency of road maintenance operations.

The high-sensitivity infrared sensor plays a crucial role by transmitting precise temperature readings to the control system. The dosing system reacts within a fraction of a second to any temperature fluctuations, automatically adjusting the amount of de-icing material applied based on the recorded data.

Maintaining the accuracy of these infrared sensors requires careful calibration, particularly given the varying emissivity and environmental conditions encountered in road maintenance. Even minor calibration errors can lead to significant inaccuracies in temperature measurements, potentially impacting decision-making. For instance, small amounts of residual moisture or thin layers of ice might not be detected accurately, leading to either underestimation or overestimation of icy conditions. This sensitivity necessitates precise calibration and ongoing monitoring to ensure reliable readings. To address these challenges, the sensors are highly sensitive and are often specifically calibrated at 0°C. Additionally, they can be adjusted for offset correction in the field, ensuring that temperature readings remain accurate.

Typically, infrared sensors measure temperature at specific points, which can result in incomplete data on temperature variations across the entire road surface. This spatial variability can make it challenging to assess the overall road condition accurately. However, the use of infrared cameras in linescanner mode addresses this issue by capturing temperature variations across the full width of the road, providing comprehensive and detailed data that enhances road condition assessments.

Cutting Costs and Environmental Impact: Advanced Road Temperature Monitoring with CSlaser and CSmicro Pyrometers

The CSlaser LT hs and CSmicro LT hs pyrometers set a new benchmark in road temperature sensing with their exceptional high sensitivity. Unlike other pyrometers with broader temperature ranges, these sensors can detect minute temperature differences as small as 25 mK. With system accuracy within ±1 °C and precision repeatability of ±0.3 °C, they offer unparalleled reliability for monitoring road conditions with unmatched precision. The CSmicro and CSlaser pyrometers are also designed for easy integration, featuring two-wire operation that supports both analog and digital modes for flexible interfacing.

In addition, Optris provides a comprehensive range of accessories for these sensors, offering versatile and customized solutions for various applications, including custom calibration and calibration certificates when required.

Adopting a more economical approach to spreading de-icing materials not only reduces environmental impact but also significantly lowers costs. By using less gritting material overall and strategically increasing application in colder areas where it’s most needed, expenses are minimized without compromising traffic safety.

This system also enhances driver efficiency by allowing them to concentrate more on driving, significantly reducing the risk of operational errors. The digital, fast-reacting system adjusts the dosage more frequently and precisely than manual methods, resulting in substantial savings in spreading material—approximately 15%.

Recommended Products

Other Condition Monitoring Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.