Non-Contact Infrared Measurement in Thermal Batteries

Ensuring Accurate State of Charge Monitoring with Two-Color Pyrometers

Harnessing Renewable Energy with Efficient Thermal Batteries for Industrial Heat and Power

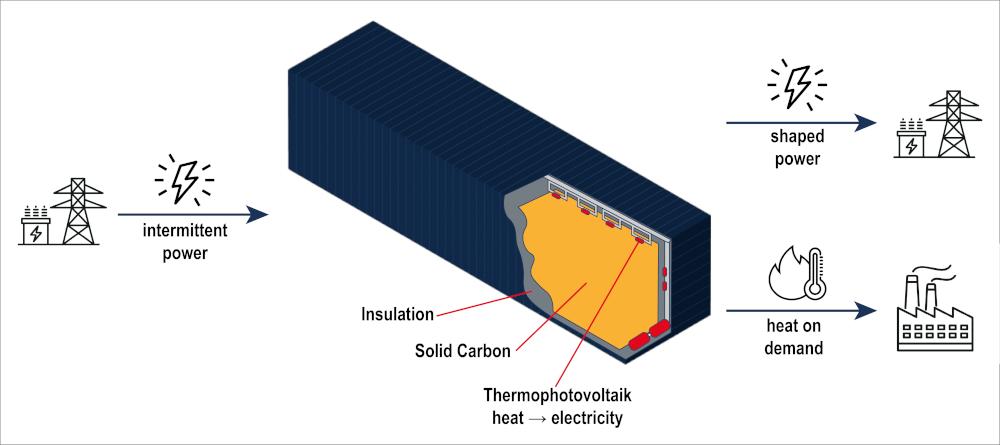

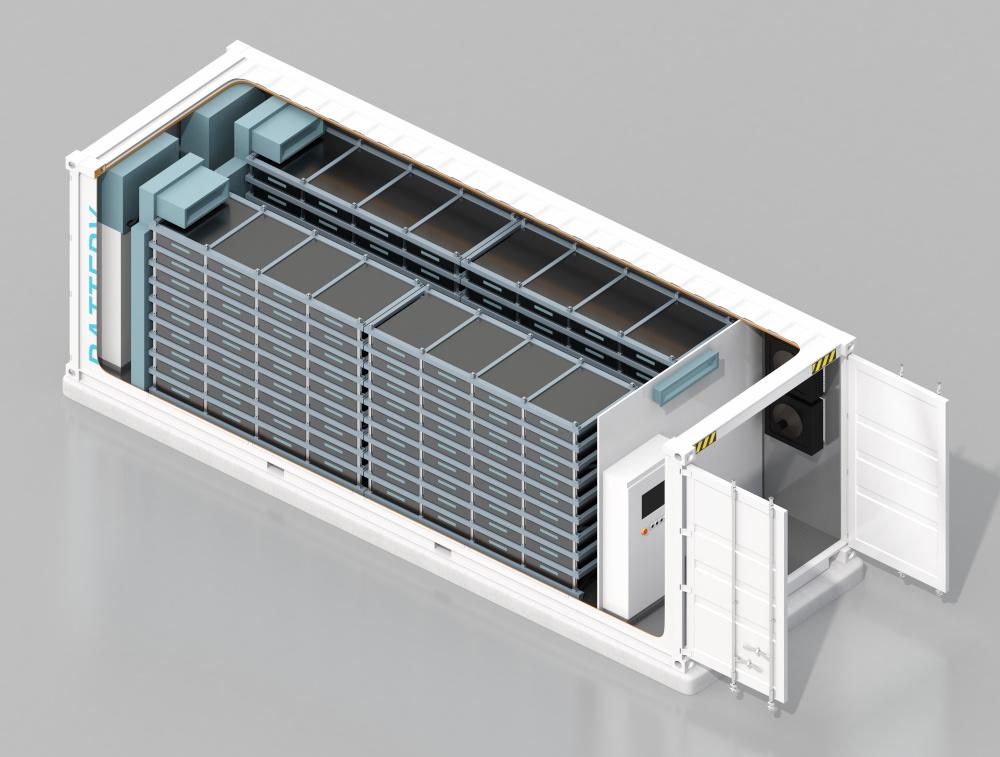

Solid-state thermal batteries, also known as heat batteries, store intermittent electrical energy—often derived from renewable sources or industrial waste heat—as thermal energy for extended periods. They provide sustainable heat and power on the scale required by large industrial operations. These thermal batteries use solid materials to store thermal energy at high temperatures within insulated modules for high-energy storage applications. Materials such as glass slag, steel slag, concrete, silicon, and graphene are utilized for their high-temperature, energy-dense storage capabilities.

While various companies employ slightly different methods to generate and store heat, the underlying principle remains consistent: renewable energy sources like wind and solar heat cost-effective materials, which are then insulated until the stored heat can be discharged for manufacturing purposes.

These thermal energy storage systems, often container-sized, heat large masses of material in insulated, sometimes evacuated chambers to temperatures ranging from 650 °C to 3000 °C, with typical operational temperatures around 1200 °C. High-efficiency photovoltaics capture the radiated energy from the glowing-hot material, or the heat is directly applied to industrial processes. This stored heat is then delivered at the necessary scale and temperature for various industrial applications.

The state of charge is measured by the temperature of the mass, which must be monitored to control the battery. Contact temperature measurement is not feasible due to interference from wiring, and insulation issues. Traditional contact methods also fail at such extreme temperatures due to the temperature range or sensor drift. This underscores the crucial necessity of non-contact infrared measurement in monitoring thermal batteries.

Accurate State of Charge Measurement in Thermal Batteries with Two-Color Pyrometers

The state of charge in thermal batteries is directly correlated to the temperature of the thermal mass. Given these batteries’ large energy capacity, the temperature of the employed material can vary significantly. Over such a wide range of temperatures, changes in the material’s emissivity can lead to inaccurate temperature readings.

To address this, the two-color principle of infrared thermometry can be applied to measure temperature accurately. A two-color pyrometer measures temperature by comparing the intensity of radiation emitted at two different wavelengths from a surface. Unlike single-wavelength pyrometers, which rely on the absolute intensity at one wavelength, two-color pyrometers calculate temperature based on the ratio of the intensities at the two wavelengths. This ratio-based measurement is less affected by changes in emissivity, making it more reliable over varying temperatures. Consequently, this method compensates for variations in emissivity, ensuring accurate temperature readings even when the thermal mass experiences significant temperature fluctuations.

Optris offers different ratio pyrometers with the smart ratio mode. The smart ratio mode of ratio pyrometers enhances temperature measurement accuracy as this automatically adapts to variations in the measurement environment, such as changes in emissivity after a teach-in. The smart ratio mode ensures precise and repeatable temperature readings by continuously analyzing and adjusting the ratio of radiation intensities at two wavelengths.

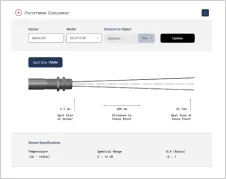

Integrating Optris Pyrometers for Superior Thermal Battery Monitoring

An industrial thermal battery system in the US has integrated the Optris CT Ratio infrared pyrometer to measure temperatures exceeding 1200°C. These devices provide precise non-contact measurement capabilities, crucial for monitoring the superheated graphite in their thermal storage system. The high optical resolution and robust design of Optris pyrometers ensure accurate temperature readings even in the challenging conditions of an enclosed chamber. Additionally, integrating Optris devices with existing process control systems via 4-20mA outputs enables seamless data analysis and process optimization, ensuring high efficiency in energy recapture.

The Optris CT Ratio models’ robust design and high optical resolution allow for precise monitoring of superheated thermal mass, revealing the energy storage capacity and enabling process optimization. Furthermore, Optris’ comprehensive software support and advanced algorithms, such as the smart ratio mode, enhance the overall effectiveness and efficiency of the thermal storage system, making Optris the preferred choice for battery monitoring applications.

Recommended Products

Other Battery Monitoring Applications

Talk to us about your IR Temperature Measurement Requirements

There are over 300 different pyrometer variants to choose from in the Optris infrared pyrometer portfolio each optimized for material, spot size, distance from the target, and environmental conditions. Fortunately, there is a trained engineer to phone or chat with to guide you through the process of choosing the perfect infrared sensor for your application.

The same support is available for the extensive IR camera product line.